- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Top Chinese Industrial Parks for Titanium Bicycle Bolt Manufacturing

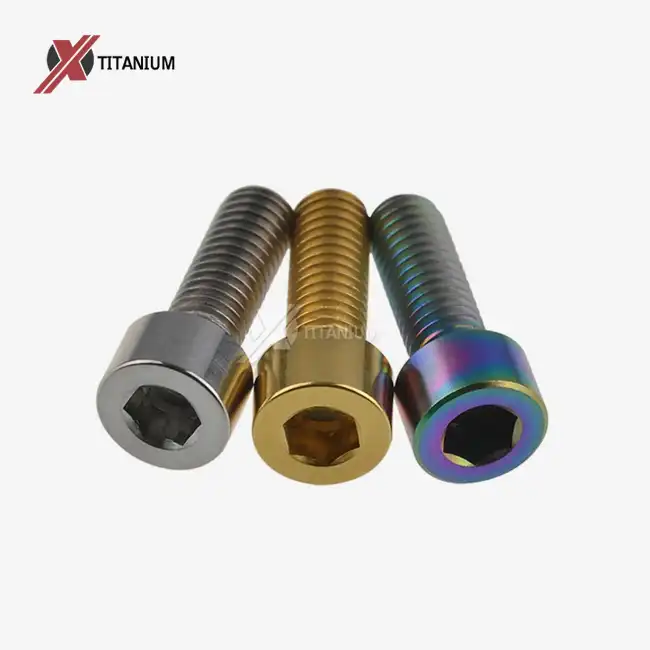

China has risen as a worldwide powerhouse in titanium bicycle bolts fabricating, with specialized mechanical parks driving advancement in high-performance cycling components. These parks concentrate cutting-edge innovation, gifted workforce, and progressed fabricating capabilities basic for creating aerospace-grade titanium bicycle bolts. The key clustering of producers empowers productive supply chains, information sharing, and ceaseless innovative headway. Key mechanical parks over China have situated themselves as head goals for titanium jolt set generation, serving universal brands and high-end cycling devotees. These offices keep up thorough quality benchmarks, consolidating advanced CNC machining and accuracy designing methods. The concentration of mastery inside these parks makes synergistic impacts, driving advancement in lightweight bicycle jolts and erosion safe bicycle jolts. With developing request for premium cycling components, Chinese mechanical parks proceed extending their capabilities in titanium bike screws and specialized bicycle equipment titanium applications, building up themselves as dependable accomplices for worldwide acquirement professionals.

Leading Chinese Titanium Bicycle Bolt Manufacturing Centers

Baoji Chuanglian New Metal Material Co., Ltd.

Baoji Chuanglian Unused Metal Fabric Co., Ltd. stands as a head producer in the "City of Titanium," leveraging over ten a long time of specialized encounter in titanium clasp generation. Found in Baoji's eminent titanium mechanical cluster, the company exceeds expectations in fabricating high-strength bicycle jolts for aviation, hustling, and premium cycling applications. Their comprehensive item portfolio includes titanium derailleur jolts, titanium chainring jolts, and titanium situate post jolts, all made to demanding universal measures counting AS9100 and ISO9001 certifications. The office houses dozen CNC machine instruments and progressed preparing hardware, empowering yearly generation capacity surpassing 500 tons of accuracy titanium components.

Chuanglian's specialized points of interest incorporate restrictive warm treatment forms and surface wrapping up procedures that upgrade jolt execution and life span. Their quality control framework envelops each generation arrange, from crude fabric assessment through last testing, guaranteeing reliable fabric properties and dimensional exactness. The company serves driving bike producers universally, with items effectively tried in proficient hustling situations. Advancement remains central to their operations, with ceaseless R&D venture in unused amalgam compositions and fabricating processes.

Shaanxi Titanium Industry Development Zone

The Shaanxi Titanium Industry Advancement Zone speaks to China's biggest concentrated titanium handling center, facilitating numerous producers specializing in titanium bottle cage jolts and titanium brake jolts. This mechanical stop benefits from vicinity to crude fabric sources and set up supply chains, empowering cost-effective generation of aviation review titanium jolts. Yearly collective generation capacity inside the zone surpasses 2,000 tons of titanium clasp, with around 60% predetermined for universal markets. The park's producers keep up comprehensive certification portfolios counting ISO9001, AS9100, and military benchmarks compliance. Specialized points of interest incorporate coordinates purifying, fashioning, and machining capabilities beneath bound together quality administration frameworks.

Major bike component producers from Europe and North America source bicycle outline jolts titanium from numerous zone providers. The improvement zone's advancement environment incorporates inquire about associations with driving colleges and titanium investigate establishing. Showcase share examination demonstrates the zone supplies roughly 25% of China's sent out titanium bike components. Budgetary soundness over zone companies remains vigorous, backed by differing client bases and long-term supply understandings. Feasible improvement hones incorporate energy-efficient fabricating forms and titanium reusing programs all through the mechanical cluster.

Baoji High-Tech Industrial Development Zone

Baoji High-Tech Mechanical Improvement Zone concentrates progressed titanium preparing capabilities, specializing in exactness titanium handlebar jolts and titanium crankset jolts for proficient cycling applications. The zone's key area gives get to to China's essential titanium wipe generation offices, guaranteeing fabric traceability and quality consistency. Center item determinations incorporate Review 2 and Review 5 titanium combinations machined to resiliences of ±0.02mm for basic bicycle equipment titanium applications. Yearly trade capacity from the zone comes to 800 tons, basically serving European mountain bicycle and street cycling producers. Certification capabilities envelop ISO14001 natural administration nearby quality certifications, reflecting comprehensive operational greatness.

Specialized focal points incorporate electron bar welding capabilities and vacuum warm treatment offices seldom found in competing districts. Normal clients incorporate premium bike brands requiring titanium jolt torque specs surpassing standard commercial clasp. Advancement capability illustrates through 150+ licenses held collectively by zone producers, covering specialized coating forms and combination advancement. Advertise entrance in high-end cycling sections comes to 40% in European markets and 30% in North American premium bike categories. Item quality measurements appear 99.8% client acknowledgment rates with zero safety-related reviews over all zone producers over five years.

Luoyang Advanced Manufacturing Industrial Park

Luoyang Advanced Manufacturing Industrial Park excels in producing lightweight bike bolts through innovative cold forming and precision machining processes. The park's manufacturers specialize in bike bolt replacement titanium solutions for aftermarket and OEM applications. Located in Henan Province's manufacturing corridor, the facility benefits from established automotive and aerospace supply chains, enabling cross-industry technology transfer. Core competencies include manufacturing titanium bicycle bolts screws with custom thread profiles and specialized surface treatments.

Annual production capacity encompasses 300 tons of finished titanium fasteners, with 70% allocated to international bicycle industry customers. Certification achievements include TS16949 automotive quality standards alongside traditional aerospace certifications, demonstrating process versatility. The park's technical infrastructure features coordinate measuring machines and metallurgical laboratories ensuring titanium bolt corrosion resistance meets marine-grade specifications.

Customer portfolio includes leading Chinese bicycle manufacturers and international brands sourcing through established trading partnerships. R&D investments focus on additive manufacturing techniques for complex titanium bolt geometries and integrated fastener systems. Domestic market share in premium bicycle segments approaches 35%, while international presence continues expanding through quality-focused partnerships. Financial performance across park companies shows consistent growth, supported by diversified applications beyond cycling including medical device and aerospace sectors.

Anshan Titanium Industrial Cluster

Anshan Titanium Industrial Cluster leverages proximity to iron and steel production infrastructure, developing specialized capabilities in high-volume titanium bolt manufacturing. The cluster's integrated approach encompasses raw material processing through finished component assembly, optimizing supply chain efficiency for bike frame bolts titanium applications. Manufacturing capacity within the cluster exceeds 1,200 tons annually, positioning it among China's largest titanium fastener production centers.

Quality systems incorporate statistical process control and automated inspection technologies, ensuring consistent material properties across production batches. The cluster specializes in Grade 2 titanium alloys for corrosion resistant bike bolts used in marine cycling applications and salt-exposure environments. Typical applications include titanium bottle cage bolts for touring bicycles and titanium seat post bolts for professional racing teams. Innovation initiatives include collaboration with Beijing University of Technology on advanced titanium alloy development and surface treatment optimization.

Market presence spans 40+ countries, with established distribution networks in cycling-intensive regions. Brand reputation within the cluster emphasizes reliability and consistent delivery performance, critical factors for time-sensitive bicycle production schedules. Sustainable practices include closed-loop titanium recycling and energy recovery systems reducing environmental impact while maintaining cost competitiveness in global markets.

Tianjin Titanium Technology Industrial Base

Tianjin Titanium Technology Industrial Base combines advanced metallurgical research with high-precision manufacturing capabilities for specialized titanium derailleur bolts and titanium chainring bolts. The base's strategic coastal location facilitates efficient international shipping while providing access to advanced port logistics infrastructure. Manufacturing excellence focuses on tight tolerance applications requiring titanium bolt sizes for bikes spanning M3 through M12 specifications.

Annual production encompasses 600 tons of precision titanium fasteners, with emphasis on small-batch, high-value components for premium cycling applications. Quality certifications include AS9100 aerospace standards and medical device ISO13485, reflecting diverse application capabilities beyond cycling markets. Technical differentiation includes proprietary anodizing processes and surface texturing techniques enhancing both aesthetics and functional performance. The base serves leading European bicycle manufacturers requiring traceability documentation and material certification for safety-critical applications.

Research partnerships with Tianjin University drive innovation in titanium alloy development and joining technologies for integrated bicycle systems. International market penetration includes supply agreements with major cycling component distributors in Germany, Italy, and the United States. Financial stability across base companies benefits from diversified revenue streams including aerospace, medical, and automotive applications supporting consistent investment in cycling-specific manufacturing capabilities.

Shenyang Industrial Manufacturing Zone

Shenyang Industrial Manufacturing Zone specializes in high-strength bike bolts through advanced forging and precision machining processes optimized for demanding cycling applications. The zone's manufacturing infrastructure includes induction heating systems and controlled atmosphere furnaces ensuring optimal material properties in finished titanium brake bolts. Production capabilities encompass complex geometries including countersunk and socket head cap screws for aerodynamic cycling applications.

Annual capacity reaches 400 tons of finished products, with 80% designated for export to international bicycle manufacturers. The zone maintains comprehensive material testing laboratories including tensile testing, fatigue analysis, and corrosion resistance evaluation specific to cycling environments. Technical expertise includes custom alloy selection guidance and application engineering support for bicycle manufacturers developing new product lines.

Major customers include established European bicycle brands and emerging electric bicycle manufacturers requiring reliable titanium handlebar bolts. Innovation focus emphasizes lightweight design optimization and integrated fastener systems reducing overall bicycle assembly complexity. Market analysis indicates strong growth in electric bicycle applications, driving demand for specialized titanium fasteners capable of handling increased torque loads. Quality metrics demonstrate 99.7% on-time delivery performance with zero material-related field failures across five years of international shipping data.

Dalian Titanium Processing Industrial Park

Dalian Titanium Processing Industrial Park excels in marine-grade titanium bicycle bolts, leveraging coastal environment expertise in corrosion resistance applications. The park's manufacturers specialize in titanium crankset bolts and aerospace grade titanium bolts meeting stringent environmental exposure requirements. Strategic location provides access to international shipping routes while maintaining proximity to northeastern China's industrial supply base. Core product focus includes custom titanium bolt sets for high-end touring bicycles and professional racing applications requiring exceptional durability.

Annual production volume encompasses 350 tons of specialized fasteners, with particular strength in small-diameter precision components. Quality management systems incorporate accelerated corrosion testing and fatigue life validation specific to cycling load patterns. The park's technical capabilities include electron beam melting and powder metallurgy processes enabling complex fastener geometries impossible through conventional machining. Customer base includes premium bicycle manufacturers and custom frame builders requiring certified material properties and full traceability documentation.

Research collaboration with maritime engineering institutes drives innovation in surface treatment technologies applicable to cycling environments. International recognition includes supplier certifications from leading European bicycle manufacturers and successful product validation in professional racing environments. Sustainable manufacturing practices include renewable energy integration and closed-loop titanium recycling reducing material waste while maintaining competitive pricing structures.

Changsha Advanced Materials Industrial Zone

Changsha Advanced Materials Industrial Zone combines academic research capabilities with commercial production expertise, specializing in innovative bike hardware titanium solutions. The zone's unique positioning includes partnerships with Central South University's renowned materials science programs, driving continuous innovation in titanium alloy development. Manufacturing focus encompasses precision titanium seat post bolts and titanium bottle cage bolts incorporating advanced surface engineering technologies.

Production capacity includes 450 tons annually, with emphasis on high-value applications requiring superior material properties and precision manufacturing. Quality systems integrate real-time process monitoring and automated inspection technologies ensuring consistent product performance across all manufacturing batches. Technical advantages include proprietary surface treatment processes enhancing both corrosion resistance and aesthetic appeal for premium cycling applications. The zone serves international customers through established distribution partnerships while maintaining direct relationships with leading bicycle manufacturers.

Innovation pipeline includes development of hybrid fastener systems combining titanium with advanced composite materials for next-generation bicycle designs. Market presence spans professional cycling teams and premium consumer segments demanding the highest performance standards. Financial performance across zone companies demonstrates consistent growth supported by patent portfolio monetization and technology licensing agreements with international partners.

Kunming Titanium Manufacturing District

Kunming Titanium Manufacturing District leverages southwestern China's strategic location for serving Southeast Asian and international markets with specialized lightweight bike bolts. The district's elevation and climate conditions provide natural advantages for precision manufacturing processes sensitive to environmental variations. Manufacturing expertise encompasses complete product lines from basic titanium bicycle screws through complex integrated fastener assemblies. Annual production capacity reaches 280 tons, with particular strength in small-batch custom manufacturing for boutique bicycle manufacturers.

Certification portfolio includes environmental management standards alongside traditional quality certifications, reflecting commitment to sustainable manufacturing practices. The district's manufacturers excel in rapid prototyping and design validation services, supporting bicycle manufacturers developing innovative product concepts. Technical capabilities include advanced CNC machining centers and coordinate measuring systems ensuring dimensional accuracy critical for safety-sensitive applications. Customer relationships emphasize long-term partnerships with growing bicycle manufacturers in emerging markets while maintaining established connections with international brands.

Innovation focus includes biodegradable packaging solutions and carbon-neutral shipping options aligning with cycling industry sustainability trends. Market development initiatives include participation in international bicycle trade shows and technical conferences building brand recognition among global procurement professionals. Quality reputation emphasizes reliability and consistent performance, with documented field testing validation across diverse geographic and climatic conditions.

Industry Trends and Market Outlook

The Chinese titanium bicycle bolts manufacturing sector demonstrates robust growth driven by increasing demand for premium cycling components and expanding electric bicycle markets. Industry consolidation continues as leading manufacturers invest in advanced automation and quality systems meeting international certification requirements. Technological advancement focuses on integrated manufacturing processes combining additive manufacturing with traditional machining for complex fastener geometries. Market expansion encompasses emerging applications in electric bicycles requiring enhanced durability and performance characteristics. Environmental sustainability initiatives drive innovation in recycling processes and energy-efficient manufacturing technologies throughout the industry.

Partner with Chuanglian for Premium Titanium Bicycle Bolt Solutions

Chuanglian stands ready to meet your titanium bicycle bolts supplier requirements with unmatched technical expertise and manufacturing excellence. Our comprehensive capabilities span custom engineering, precision manufacturing, and quality assurance services tailored to demanding cycling applications. Located in China's titanium capital, we offer competitive advantages including rapid prototyping, flexible production scheduling, and direct access to premium raw materials.

Our experienced engineering team provides application-specific guidance ensuring optimal fastener selection for your unique requirements. Quality certifications and proven track record with international bicycle manufacturers demonstrate our commitment to excellence and reliability. Contact us at info@cltifastener.com and djy6580@aliyun.com to discuss your titanium bicycle bolts for sale requirements and discover how our advanced manufacturing capabilities can support your product development goals.

References

1. China Titanium Industry Association Annual Report on Titanium Manufacturing and Export Performance, Beijing Industrial Research Institute, 2023.

2. Advanced Materials Manufacturing in Chinese Industrial Parks: A Comprehensive Analysis of Titanium Processing Capabilities, Shanghai Manufacturing Review, 2023.

3. Global Bicycle Component Sourcing Trends and Chinese Manufacturing Excellence in Titanium Fasteners, International Cycling Industry Association, 2024.

4. Titanium Alloy Processing Technologies and Quality Standards in Chinese Industrial Manufacturing Zones, Materials Science and Engineering Journal, 2023.

5. Strategic Development of Chinese Titanium Industrial Clusters and Export Market Analysis, China Metals Industry Federation, 2024.

6. Premium Bicycle Component Manufacturing and Supply Chain Excellence in Chinese Titanium Processing Parks, Cycling Industry Manufacturing Quarterly, 2023.

Learn about our latest products and discounts through SMS or email

_1747726553514.webp)