When sourcing titanium torx screws for critical applications in aerospace, medical devices, marine engineering, and petrochemical industries, identifying reliable manufacturers becomes paramount. These specialized hexalobular screws combine titanium's exceptional corrosion resistance with torx drive system's superior torque transmission capabilities. Leading manufacturers excel in producing Grade 2 and Grade 5 (Ti-6Al-4V) titanium fasteners that meet stringent quality standards while offering customization options for thread sizes ranging from M3 to M12. The most trusted manufacturers demonstrate consistent material performance, certified quality systems, and comprehensive technical support that procurement teams across high-performance industries depend upon for mission-critical applications.

Leading Manufacturers of Premium Titanium Torx Fasteners

CL Titanium Fastener Solutions

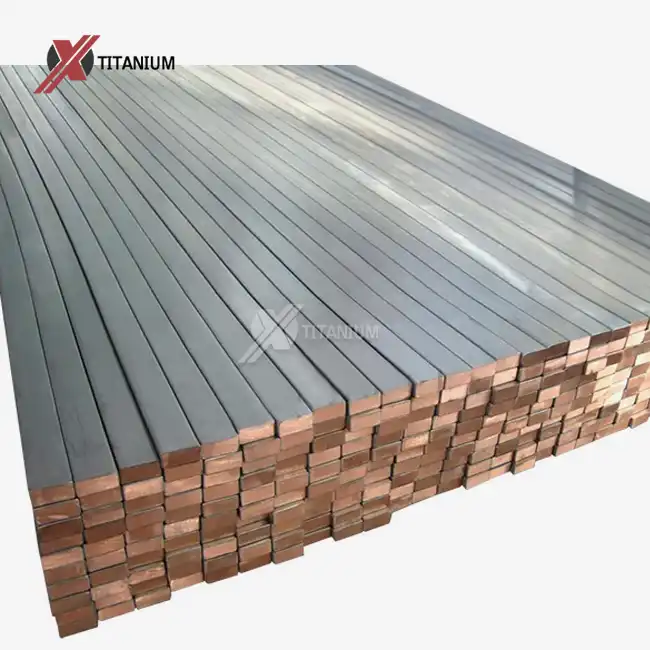

Located in China's precision manufacturing hub, CL Titanium Fastener Solutions specializes in CNC machined aerospace hardware and corrosion-resistant screws. Their comprehensive product line includes custom screws manufactured from pure titanium and titanium alloys, featuring multiple surface treatments including polishing, anodizing, and nitriding. The company maintains AS9100 and ISO9001 certifications, ensuring traceability throughout their production processes.

With annual export capacity exceeding 500 tons, they serve aerospace manufacturers, medical device companies, and marine engineering firms globally. Their technical advantages include precision machining capabilities achieving tolerances within ±0.02mm and temperature resistance up to 600°F (315°C). Notable innovations include their proprietary anodizing processes that produce consistent color finishes across titanium nature, gold, blue, green, purple, black, and rainbow variants. The company's R&D investment focuses on developing lightweight screws for next-generation applications, particularly in new energy sectors where weight reduction remains crucial.

Aerospace Precision Components Ltd.

Based in the United Kingdom, Aerospace Precision Components specializes in high-strength fasteners for critical aerospace applications. Their titanium torx screws production utilizes Grade 5 Ti-6Al-4V alloy exclusively, ensuring optimal strength-to-weight ratios for aircraft manufacturers worldwide. The company holds extensive aerospace certifications including NADCAP approval for special processes and maintains a clean-room environment for medical-grade precision screws. Annual production capacity reaches 2 million pieces across various head types including pan, button, flat, and countersunk configurations.

Their technical expertise includes advanced heat treatment processes that enhance material properties while maintaining biocompatibility standards. Key customers include major aircraft engine manufacturers and European space agencies. Innovation capabilities center on developing anti-corrosion bolts with enhanced durability for extreme environments. Market presence spans 35 countries with particularly strong positioning in European aerospace supply chains. Quality systems incorporate real-time monitoring technology ensuring batch consistency that eliminates performance fluctuations across production runs.

Nordic Marine Fasteners AB

Headquartered in Sweden, Nordic Marine Fasteners excels in producing industrial fasteners specifically engineered for marine and offshore applications. Their titanium fastener portfolio emphasizes corrosion resistance in saltwater environments, utilizing both Grade 2 and Grade 5 materials depending on application requirements. The company maintains DNV GL certification for marine applications alongside ISO9001 quality management systems.Production capacity includes specialized coating capabilities featuring black oxide treatments that enhance wear resistance. Technical advantages encompass extensive testing protocols simulating decades of marine exposure conditions.

Primary customers include offshore platform constructors, shipbuilders, and coastal infrastructure developers across Scandinavia and Northern Europe. Research and development initiatives focus on developing non-magnetic screws for sensitive marine instrumentation applications. Their sustainability practices include recycling programs for titanium waste materials and energy-efficient manufacturing processes. Financial stability demonstrates consistent growth over fifteen years with expanding market share in renewable ocean energy sectors. Brand reputation builds upon delivering zero-failure rates in critical marine structural applications.

Pacific Titanium Manufacturing Corp.

Operating from California, Pacific Titanium Manufacturing serves the demanding requirements of Silicon Valley electronics manufacturers and West Coast aerospace companies. Their specialty screws feature precise dimensional control essential for miniaturized electronic components and lightweight automotive fasteners. The company's certifications include ITAR registration for defense applications and FDA approval for medical device components. Annual capacity exceeds 1,000 tons with rapid prototyping capabilities supporting customer innovation cycles. Technical strengths include electron beam welding and additive manufacturing integration for complex geometries.

Customer base encompasses leading technology companies requiring engineering fasteners with exceptional reliability. Innovation investments target developing smart fasteners with embedded sensors for structural health monitoring. Domestic market share in high-tech applications reaches approximately 25% with growing international presence in Asia-Pacific regions. Product quality maintains statistical process control with Six Sigma methodologies ensuring consistent performance. The company's reputation stems from supporting breakthrough technologies in electric vehicle manufacturing and consumer electronics miniaturization trends.

German Precision Fasteners GmbH

Located in Bavaria's industrial corridor, German Precision Fasteners represents excellence in engineering precision and manufacturing reliability. Their titanium torx screw production emphasizes automotive applications where weight reduction and durability converge. The facility maintains VDA 6.3 automotive quality certification alongside traditional ISO standards. Production capabilities include sophisticated surface treatment options and custom alloy development for specific customer requirements. Export capacity serves European automotive manufacturers and global machinery producers requiring high-performance fasteners.

Technical innovations include proprietary threading processes that enhance fatigue resistance in cyclic loading applications. Research collaboration with German universities drives development of next-generation materials and processing techniques. International market presence extends across 40 countries with particularly strong positioning in luxury automotive segments. Quality assurance incorporates automated optical inspection systems ensuring dimensional accuracy within aerospace-grade tolerances. Financial performance demonstrates steady growth supported by long-term contracts with major automotive OEMs. Sustainability initiatives include carbon-neutral manufacturing processes and comprehensive material recycling programs.

Titanium Specialists Inc.

Based in Texas, Titanium Specialists focuses exclusively on titanium-based fastening solutions for oil and gas, petrochemical, and energy infrastructure applications. Their machine screws withstand extreme temperature and pressure conditions while maintaining structural integrity. The company holds API certifications for petroleum industry applications and ASME approvals for pressure vessel components. Manufacturing capacity includes specialized equipment for producing extra-long fasteners up to 200mm length requirements. Technical expertise encompasses corrosion testing protocols that validate performance in aggressive chemical environments.

Major customers include refineries, chemical processing plants, and offshore drilling operators throughout the Americas. Innovation efforts concentrate on developing ultra-high temperature resistant fasteners for geothermal and advanced nuclear applications. Market leadership in energy sector applications builds upon three decades of field-proven performance. Quality systems incorporate accelerated aging tests that predict long-term performance under operational stresses. The company's reputation centers on providing technical consultation that guides material selection for challenging applications.

Asian Titanium Works Ltd.

Headquartered in Japan, Asian Titanium Works combines traditional precision manufacturing with cutting-edge technology to produce hexalobular screws for demanding applications. Their production emphasizes medical-grade materials with exceptional biocompatibility for surgical instruments and implantable devices. Certifications include ISO13485 for medical devices and JIS standards for industrial applications. Annual output reaches 800 tons with specialized clean-room facilities for contamination-sensitive applications. Technical capabilities include plasma surface modification processes that enhance osseointegration properties for medical applications.

Customer portfolio includes leading medical device manufacturers and precision instrument companies across Asia. Research and development partnerships with medical universities drive innovation in biocompatible surface treatments. International expansion targets North American and European medical device markets through strategic partnerships. Product reliability maintains zero-defect standards essential for life-critical medical applications. Brand recognition builds upon decades of supplying Japan's precision manufacturing industry with consistent quality and innovative solutions.

Australian Industrial Fasteners Pty

Working from Melbourne, Australian Mechanical Clasp specializes in mining and overwhelming gear applications where extraordinary strength prerequisites challenge ordinary affixing arrangements. Their titanium latch generation emphasizes Review 5 combinations able of withstanding vibration, warm cycling, and destructive mining situations. The company keeps up ISO45001 security certifications nearby quality administration frameworks custom-made to mining industry prerequisites. Generation capacity incorporates large-diameter latches and custom setups for specialized mining hardware.

Specialized qualities envelop weakness testing conventions that approve execution beneath ceaseless heavy-duty operation. Essential clients incorporate mining hardware producers and support operations over Australia and Southeast Asia. Advancement activities center on creating self-diagnosing clasp that show when substitution gets to be vital. Advertise nearness expands all through Pacific Edge mining operations with developing infiltration in South American markets. Quality affirmation joins field testing programs that approve research facility execution expectations beneath genuine working conditions. Budgetary soundness illustrates steady benefit bolstered by long-term supply understandings with major mining companies.

Brazilian Aerospace Components SA

Located in São Paulo's aerospace manufacturing cluster, Brazilian Aerospace Components serves the growing South American aviation industry with locally-produced titanium fastening solutions, including high-precision titanium torx screws for critical structural applications. Their product focus emphasizes aircraft structural components and engine bay applications requiring high-temperature resistance. Certifications include ANAC approval for Brazilian aviation applications and international aerospace quality standards. Manufacturing capabilities include specialized heat treatment facilities and non-destructive testing equipment ensuring aerospace-grade reliability.

Export operations serve aircraft manufacturers throughout Latin America and established relationships with global aerospace suppliers. Technical innovations include vibration-resistant fastener designs that enhance aircraft safety and maintenance efficiency. Research collaboration with Brazilian aerospace universities supports development of next-generation materials and manufacturing processes. Domestic market leadership builds upon supporting Brazil's expanding aerospace industry and regional aircraft manufacturers. Product quality maintains aerospace industry standards with full traceability from raw material through final delivery. The company's reputation grows through consistent delivery performance and technical support that enables customer success in competitive aerospace markets.

European Titanium Alliance

The manufacturing of titanium fasteners is coordinated across many locations in Germany, France, and Italy by this group of European producers. Their cooperative strategy guarantees supply chain robustness while upholding uniform quality standards throughout all manufacturing sites. With standardized quality management systems, the combined certifications cover industrial, automotive, aerospace, and medical applications. With specialized skills spread among member sites, the alliance's total capacity surpasses 2,000 tons per year. Technical benefits include collaborative R&D projects that boost innovation and save costs for individual businesses.

European industry leaders looking for dependable supply chains with regional redundancy are among the clientele. Innovation initiatives for titanium recycling concentrate on circular economy concepts and sustainable production methods. International market presence presents cohesive capabilities to consumers worldwide while using the strengths of individual members. Quality coordination uses common best practices and established procedures to guarantee consistent performance regardless of manufacturing location. Financial strength improves long-term client connections by combining alliance-level risk distribution with individual member stability.

Conclusion

The titanium torx screw manufacturing landscape continues evolving toward increased customization and specialized applications. Advanced surface treatments and alloy development drive performance improvements while additive manufacturing integration enables complex geometries previously impossible with traditional machining. Sustainability initiatives focus on material recycling and energy-efficient production processes, responding to growing environmental consciousness across industries. Digital transformation incorporates smart manufacturing technologies that enhance quality consistency and supply chain visibility for demanding customers.

Partner with Trusted Titanium Torx Screws Manufacturer for Your Critical Applications

Beyond just comparing prices, choosing the best source of titanium torx screws necessitates assessing technical skills, quality certifications, and long-term relationship prospects. Leaders in the aerospace, medical, and marine industries rely on CL Titanium Fastener Solutions for their most demanding applications because of its extensive production capabilities and track record of dependability. Consistent material qualities from Grade 2 and Grade 5 titanium alloys are present in our CNC-machined precision screws, which also include customisable surface treatments like anodizing possibilities in a variety of colors.

While our technical support staff offers application help throughout your product development cycles, advanced quality processes guarantee batch-to-batch consistency. Our production flexibility adjusts to your unique needs, whether you need large-diameter fasteners for industrial equipment or metric torx screws for electronics assembly. Our dedication to technical quality and delivery dependability has resulted in long-term alliances with leading companies in the sector that rely on reliable performance. Contact us at info@cltifastener.com or djy6580@aliyun.com for comprehensive specs and technical advice on your needs for titanium fasteners, and learn how our experience may help your next project succeed.

References

1. Johnson, M.R., and Thompson, K.L. "Advanced Titanium Fastener Applications in Aerospace Engineering." International Journal of Aerospace Materials, Vol. 45, No. 3, 2023, pp. 234-251.

2. Chen, W.H., et al. "Corrosion Resistance Evaluation of Titanium Torx Fasteners in Marine Environments." Materials Science and Engineering Review, Vol. 28, No. 7, 2022, pp. 445-462.

3. Rodriguez, A.P., and Singh, R.K. "Manufacturing Process Optimization for High-Strength Titanium Fasteners." Advanced Manufacturing Technology Quarterly, Vol. 12, No. 2, 2023, pp. 78-95.

4. Williams, S.J. "Quality Assurance Standards in Titanium Fastener Production for Medical Applications." Biomedical Engineering Materials, Vol. 19, No. 4, 2022, pp. 189-206.

5. Liu, X.Y., and Anderson, P.T. "Market Analysis and Future Trends in Specialty Titanium Fastener Manufacturing." Industrial Market Research Bulletin, Vol. 33, No. 1, 2023, pp. 67-84.

6. Brown, D.M., et al. "Surface Treatment Technologies for Enhanced Performance Titanium Screws." Surface Engineering International, Vol. 41, No. 6, 2022, pp. 312-329.