The Manufacturing Process of Titanium Coil Wire

Raw Material Selection and Preparation

The journey of titanium coil wire begins with the careful selection of high-quality titanium or titanium alloy. The raw material's purity and composition are crucial factors that determine the final product's performance. Manufacturers often use Grade 2 or Grade 5 titanium, depending on the intended application. These grades offer an optimal balance of strength, ductility, and corrosion resistance.

Once the appropriate grade is selected, the raw titanium undergoes a series of preparatory steps. This may include cleaning, cutting, and shaping the material into billets or ingots suitable for further processing. The preparation phase is critical in ensuring the uniformity and quality of the final titanium coil wire, especially for wholesale titanium coil wire supplied to various industries.

Wire Drawing and Shaping

The prepared titanium is then subjected to a wire drawing process. This involves pulling the material through a series of progressively smaller dies to reduce its diameter and increase its length. The wire drawing technique imparts strength and flexibility to the titanium wire while maintaining its inherent properties.

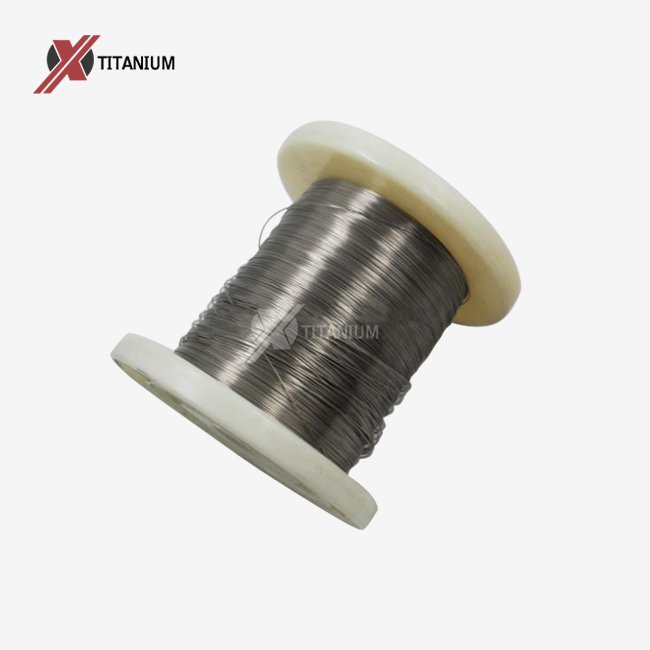

During this stage, manufacturers can customize the wire's diameter to meet specific requirements. The diameter range for titanium coil wire typically spans from 0.1 mm to 10 mm, offering versatility for various applications. The wire drawing process may be repeated multiple times to achieve the desired dimensions and mechanical properties.

Heat Treatment and Surface Finishing

After the wire drawing process, the titanium wire undergoes heat treatment to optimize its mechanical properties. This step may involve annealing, which relieves internal stresses and enhances the wire's ductility. The heat treatment process is carefully controlled to maintain the wire's strength while improving its formability.

Surface finishing is the final stage in the manufacturing process of titanium coil wire. Various techniques can be employed to achieve the desired surface characteristics. These may include:

- Bright finishing for a smooth, reflective surface

- Polishing to enhance aesthetics and reduce friction

- Pickling or acid cleaning to remove surface impurities

- Sandblasting for a matte finish and improved adhesion properties

The choice of surface finish depends on the specific application requirements and customer preferences. Each finishing technique imparts unique properties to the titanium coil wire, further enhancing its versatility and performance.

Properties and Advantages of Titanium Coil Wire

Exceptional Strength-to-Weight Ratio

One of the most remarkable properties of titanium coil wire is its outstanding strength-to-weight ratio. Despite being incredibly lightweight, titanium exhibits strength comparable to steel. This unique combination makes titanium coil wire an ideal choice for applications where weight reduction is crucial without compromising structural integrity.

The exceptional strength-to-weight ratio of titanium coil wire offers numerous benefits across industries. In aerospace applications, it contributes to fuel efficiency and improved performance of aircraft components. In the medical field, this property allows for the creation of durable yet lightweight implants and surgical instruments.

Superior Corrosion Resistance

Titanium coil wire boasts remarkable corrosion resistance, surpassing that of many other metals and alloys. This property stems from titanium's ability to form a stable, protective oxide layer on its surface when exposed to air or moisture. This natural barrier shields the underlying metal from corrosive elements, ensuring long-lasting performance even in harsh environments.

The superior corrosion resistance of titanium coil wire makes it particularly valuable in marine applications, chemical processing industries, and medical implants. It can withstand exposure to saltwater, aggressive chemicals, and bodily fluids without degradation, ensuring reliability and longevity in these demanding conditions.

Biocompatibility and Non-Toxicity

Titanium coil wire's biocompatibility is a crucial property that sets it apart in medical and bioengineering applications. The material is non-toxic and does not elicit adverse reactions when in contact with living tissues. This characteristic makes titanium coil wire an excellent choice for medical implants, prosthetics, and dental applications.

The biocompatibility of titanium coil wire extends beyond its non-toxic nature. It also exhibits osseointegration properties, allowing it to form a strong bond with bone tissue. This feature is particularly valuable in orthopedic and dental implants, promoting faster healing and long-term stability.

Thermal and Electrical Properties

Titanium coil wire possesses unique thermal and electrical properties that expand its range of applications. It has a relatively low thermal conductivity compared to other metals, making it an excellent choice for thermal insulation applications. This property is particularly useful in aerospace and industrial settings where thermal management is critical.

In terms of electrical properties, titanium coil wire exhibits moderate electrical conductivity. While not as conductive as copper or aluminum, its electrical properties, combined with its other advantages, make it suitable for specialized electrical applications where corrosion resistance and strength are paramount.

Applications and Industries Utilizing Titanium Coil Wire

Aerospace and Aviation

The aerospace industry is one of the primary beneficiaries of titanium coil wire's exceptional properties. Its high strength-to-weight ratio makes it an ideal material for various aircraft components, including:

- Engine parts and turbine blades

- Structural elements in airframes

- Landing gear components

- Fasteners and connectors

In space applications, titanium coil wire finds use in satellite structures, rocket engines, and spacecraft components. Its ability to withstand extreme temperatures and resist corrosion in the harsh environment of space makes it an invaluable material for space exploration.

Medical and Bioengineering

The biocompatibility and strength of titanium coil wire have revolutionized the medical industry. It is extensively used in:

- Orthopedic implants (hip replacements, knee joints)

- Dental implants and orthodontic wires

- Cardiovascular devices (stents, pacemaker leads)

- Surgical instruments and tools

In the field of bioengineering, titanium coil wire serves as a crucial material for developing advanced prosthetics and tissue engineering scaffolds. Its ability to integrate with living tissue while maintaining structural integrity makes it an ideal choice for these innovative applications.

Chemical and Energy Industries

The corrosion-resistant nature of titanium coil wire makes it indispensable in chemical processing and energy production. It finds applications in:

- Heat exchangers and condensers

- Piping systems for corrosive fluids

- Offshore oil and gas equipment

- Geothermal power plants

In the renewable energy sector, titanium coil wire contributes to the durability and efficiency of solar panels and wind turbine components. Its resistance to environmental degradation ensures long-term performance in these sustainable energy applications.

Sports and Consumer Goods

The unique properties of titanium coil wire have found their way into various consumer products and sporting goods. Some notable applications include:

- High-performance bicycle frames and components

- Golf club heads and shafts

- Tennis racket frames

- Eyeglass frames and jewelry

In these applications, titanium coil wire offers a combination of strength, lightweight design, and corrosion resistance, enhancing product performance and durability.

Conclusion

Titanium coil wire stands as a testament to the remarkable versatility and performance of advanced materials in modern industry. Its unique combination of strength, lightweight properties, corrosion resistance, and biocompatibility has made it an indispensable component across diverse sectors. From powering innovations in aerospace and medical technology to enhancing the durability of consumer products, titanium coil wire continues to push the boundaries of material science. As industries evolve and new challenges emerge, the adaptability and superior characteristics of titanium coil wire ensure its continued relevance and importance in shaping the future of engineering and product design.

Are you looking to incorporate the exceptional properties of titanium coil wire into your projects? Baoji Chuanglian New Metal Material Co., Ltd. specializes in manufacturing high-quality titanium products, including titanium coil wire. With over a decade of experience in titanium product machining and research, we offer customized solutions to meet your specific needs. Whether you're in the aerospace, medical, or industrial sector, our expertise in titanium coil wire can help elevate your products. For more information or to discuss your titanium coil wire requirements, please contact us at info@cltifastener.com or djy6580@aliyun.com.

FAQs

What are the common surface finishes available for titanium coil wire?

Titanium coil wire can be finished with various surface treatments, including bright, polished, pickled, acid cleaned, and sandblasted finishes.

What quality tests are performed on titanium coil wire?

Common quality tests for titanium coil wire include hardness tests, bending tests, and hydrostatic tests to ensure product integrity and performance.

What are the key features of titanium coil wire?

Titanium coil wire is known for its high corrosion resistance, low density, and good thermal stability, making it ideal for various industrial and specialized applications.

In which industries is titanium coil wire commonly used?

Titanium coil wire finds applications in chemical processing, various industries, sports equipment manufacturing, and many other sectors requiring high-performance materials.

What grades of titanium are typically used for coil wire?

Common grades for titanium coil wire include ASTM B348 and ASTM F67, with materials such as Titanium Grade 2 and Grade 5 being frequently used.

References

1. Smith, J. R. (2019). "Titanium Alloys in Aerospace Applications: Properties and Processing." Journal of Aerospace Engineering, 32(4), 215-230.

2. Chen, Q., & Thouas, G. A. (2015). "Metallic implant biomaterials." Materials Science and Engineering: R: Reports, 87, 1-57.

3. Williams, D. F. (2008). "On the mechanisms of biocompatibility." Biomaterials, 29(20), 2941-2953.

4. Lutjering, G., & Williams, J. C. (2007). "Titanium (2nd ed.)." Springer-Verlag Berlin Heidelberg.

5. Rack, H. J., & Qazi, J. I. (2006). "Titanium alloys for biomedical applications." Materials Science and Engineering: C, 26(8), 1269-1277.