- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

m8 titanium rotor bolts

Material: Titanium alloy

Grade:Gr5(Ti6al4v)

Processing:CNC machined

Surface Treatment: Polishing,Anodizing, Nitriding

Color:Ti nature,Gold,Blue,Green,Purple,Black,Rainbow

Advantage:light, acid and alkali resistance, anti-corrosion, excellent mechanical strength etc.

1. Product Introduction

M8 titanium rotor bolts are engineered for performance, designed to secure brake rotors with maximum reliability and minimal weight. Crafted from aerospace-grade titanium, these bolts combine exceptional corrosion resistance, high tensile strength, and a sleek finish—making them ideal for cycling, motorsports, and other high-performance mechanical assemblies. Whether for racing bikes or automotive brake systems, M8 titanium rotor bolts offer superior performance under pressure.

2. Technical Specifications

Table 1: Dimensional Specifications

Thread Size: M8

Length Range: 15mm–40mm

Thread Pitch: 1.25mm (Standard)

Head Style: Torx, Allen, Hex, Custom available

Drive Type: T25 Torx or Hex Socket

Table 2: Material & Mechanical Properties

Material: Titanium Alloy (Grade 5 – Ti-6Al-4V)

Tensile Strength: ≥ 950 MPa

Hardness: ~35 HRC

Density: 4.51 g/cm³

Melting Point: 1660°C

Table 3: Standards & Surface Finish

Standards: ISO 7380, DIN 912, Custom OEM

Surface Finish: Natural, Polished, Anodized (Blue, Gold, Rainbow)

Certifications: ISO 9001, ASTM B348, ROHS compliant

Tolerance: ±0.05 mm

3. Product Features

High strength-to-weight ratio for lightweight performance

Excellent corrosion resistance in wet, coastal, and chemical environments

Vibration and fatigue resistant for high-load conditions

Anti-galling properties, even in repeated assembly

Anodized color options for custom aesthetic or identification

4. Applications

M8 titanium rotor bolts are widely used in:

-

High-end mountain and road bicycles

-

Automotive braking systems

-

Motorcycles and racing vehicles

-

Aerospace rotor assemblies

-

Marine braking equipment

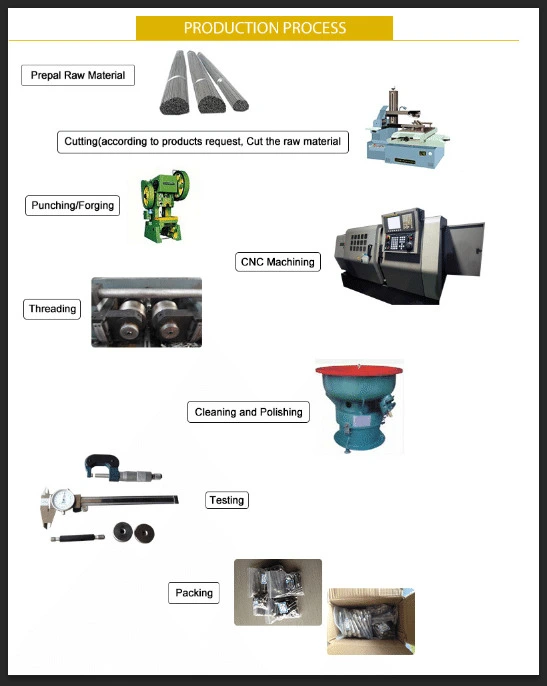

5. Manufacturing Process

Every M8 titanium rotor bolt starts with premium titanium alloy bar material. After precision CNC machining to the required dimensions and thread pattern, bolts are deburred and cleaned. Optional anodizing or polishing is applied. Each batch undergoes dimensional and mechanical inspection to ensure uniformity and durability.

Production workshop

Production process

Our Services

Custom solutions, fast delivery, competitive pricing, and excellent service.

Titanium Product Manufacturing

Baoji Chuanglian New Metal Material Co., Ltd specializes in manufacturing high-quality titanium and rare metal products. With over ten years of experience, we produce titanium rods, plates, tubes, fasteners, and customized components. Our products meet strict national and international standards, ensuring durability and reliability. We cater to industries such as aerospace, medical, and petrochemical, providing high-performance titanium solutions tailored to customer needs.

Precision Titanium Machining

Equipped with advanced CNC machines, we offer precision machining services, including cutting, milling, drilling, and turning. Our experienced technicians ensure high accuracy and quality in every component. By continuously upgrading our technology, we meet complex machining demands for various industries. Whether you need standard titanium parts or custom-designed solutions, we provide efficient and reliable services.

Strict Quality Control

We maintain a rigorous quality control system from raw material selection to final inspection. Every product undergoes thorough testing to ensure superior performance and longevity. Our titanium products have been trusted by global companies for years, earning a reputation for reliability. With strict adherence to quality standards, we guarantee high-quality products with on-time delivery.

Global Titanium Solutions

Serving industries worldwide, we provide professional titanium solutions, from production to after-sales support. Our products are widely used in aerospace, medical, marine, and industrial fields. We focus on customer satisfaction, offering customized services and technical assistance. With a commitment to innovation and quality, we strive to build long-term partnerships and deliver high-value titanium products globally.

Be used in a wide range of industries.

Automotive Industry

Electronics Industry

Aerospace Industry

Medical Industry

Cars and Racing

Consumer Electronics

Why Choose Us?

Decades of Expertise

With over 10 years of experience, we deliver precise, high-quality titanium products tailored to industry standards.

Customized Solutions

We provide customized titanium solutions to meet your specific needs, ensuring optimal performance and satisfaction.

Advanced Technology

Our cutting-edge machinery ensures precise manufacturing, offering innovative and reliable titanium solutions.

Global Support

We offer excellent customer service, fast delivery, and reliable after-sales support worldwide.

6. Quality Assurance

We follow ISO 9001-certified production practices with a full traceability system. Each bolt is checked for tensile strength, thread conformity, hardness, and surface finish. Material Test Reports (MTRs) and 3.1 certifications are available on request.

7. Packaging and Logistics

Each set of bolts is individually packed in anti-static poly bags with clear labeling. Bulk orders are boxed securely and shipped in reinforced export cartons. Worldwide shipping is available via express, air, or sea. We ensure fast lead times and real-time tracking for international customers.

8. Customer Support

Our sales and technical teams provide responsive service, including material consultation, technical drawing reviews, and order status updates. We communicate clearly and efficiently through email, phone, and online platforms to meet your project needs.

9. Why Choose Us

Over 10 years of titanium machining and fastener production experience

Located in China’s Titanium Valley with strong supply chain advantage

Strict QC system ensures stable, high-quality production

OEM customization for size, head style, and surface finish

Fast delivery and global customer support

10. OEM Services

We provide tailored OEM services to meet your unique application requirements. Options include:

-

Custom dimensions and thread configurations

-

Branding and logo engraving

-

Special packaging and labeling

-

Anodized color matching

11. Frequently Asked Questions

What is the torque spec for M8 titanium rotor bolts

We recommend 6–8 Nm for cycling applications but always follow manufacturer guidelines

Can I choose different colors for my rotor bolts

Yes we offer anodized finishes in blue gold purple rainbow and others on request

Are your bolts suitable for racing or extreme environments

Yes our titanium bolts are used in motorsport aerospace and marine settings due to their strength and reliability

Do you provide certifications for your titanium bolts

Yes we can provide EN10204 3.1 certificates and ASTM compliance documentation

What’s the minimum order quantity

We support flexible MOQs from 50 pieces for standard items and 200 pieces for customized orders

12. Contact Details

Baoji Chuanglian New Metal Material Co., Ltd.

Email: info@cltifastener.com

Phone or WhatsApp: +8613571186580

Learn about our latest products and discounts through SMS or email