- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

DIN34819 Titanium Torx Pan Head Tapping Screws

Material: Pure titanium,Titanium alloy

Grade:Gr2,Gr5(Ti6al4v)

Processing:CNC machined

Surface Treatment: Polishing,Anodizing, Nitriding

Color:Ti nature,Gold,Blue,Green,Purple,Black,Rainbow

Advantage:light, acid and alkali resistance, anti-corrosion, excellent mechanical strength etc.

DIN34819 Titanium Torx Pan Head Tapping Screws

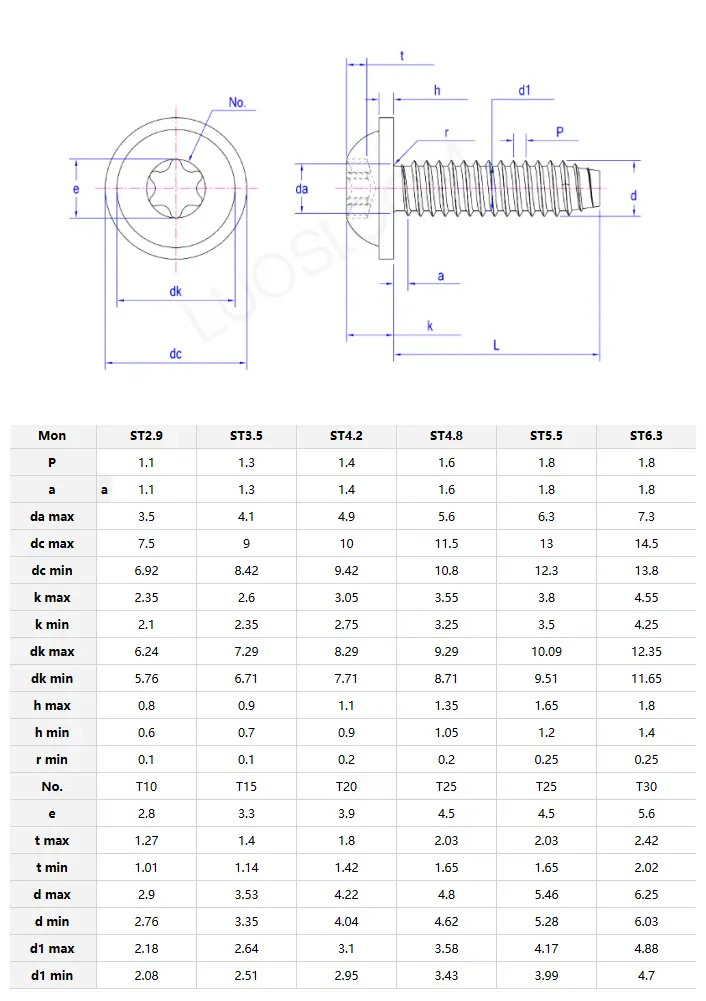

Product Parameters:DIN34819

Product Introduction

Looking for reliable and durable fastening solutions? Our DIN34819 Titanium Torx Pan Head Tapping Screws deliver exceptional performance across demanding applications. These precision-engineered fasteners combine the superior strength of titanium with the reliable design of DIN34819 specifications. Whether you're working in aerospace, marine, or high-performance automotive projects, these screws provide outstanding corrosion resistance and mechanical strength. The Torx drive system ensures secure installation and reduces cam-out risk. Our titanium tapping screws are manufactured using advanced CNC machining processes to guarantee consistent quality and precise threading.

Technical Specifications

| Parameter | Specification |

|---|---|

| Standard | DIN34819 |

| Material | Pure Titanium, Titanium Alloy |

| Grade | Gr2, Gr5 (Ti6Al4V) |

| Head Type | Pan Head |

| Drive Type | Torx |

| Processing | CNC Machined |

| Thread Type | Self-tapping |

| Surface Treatment | Polishing, Anodizing, Nitriding |

| Available Colors | Natural, Gold, Blue, Green, Purple, Black, Rainbow |

| Size Range | M3-M12 (Custom sizes available) |

| Length Range | 6mm-100mm |

| Temperature Range | -40°C to 300°C |

Key Features

Superior Corrosion Resistance: Your screws will withstand harsh environments including saltwater, chemicals, and extreme weather conditions without degradation.

Lightweight Design: Titanium's exceptional strength-to-weight ratio reduces overall assembly weight while maintaining structural integrity.

Precision Torx Drive: The six-point star design provides better torque transfer and reduces tool wear compared to traditional Phillips or slotted heads.

Self-Tapping Capability: These screws create their own threads, eliminating the need for pre-drilling in many applications.

Biocompatible: Safe for medical and food-grade applications where material purity is critical.

Product Characteristics

Our titanium Torx pan head tapping screws offer remarkable versatility and performance. The pan head design distributes load evenly across the surface, preventing material damage during installation. You'll appreciate the smooth, consistent threading that ensures reliable fastening every time.

The titanium construction provides excellent fatigue resistance, making these fasteners ideal for applications involving vibration or repeated stress cycles. Additionally, the material's natural resistance to galling means you can install and remove these screws multiple times without thread damage.

Applications

Aerospace Industry: Aircraft panels, interior components, and non-critical structural applications where weight savings and corrosion resistance are essential.

Marine Engineering: Boat fittings, deck hardware, and underwater equipment where saltwater exposure demands superior corrosion protection.

Medical Devices: Surgical instruments, prosthetics, and diagnostic equipment requiring biocompatible materials.

Automotive Racing: High-performance vehicle modifications where weight reduction and strength are crucial for competitive advantage.

Chemical Processing: Equipment assembly in corrosive environments where standard steel fasteners would fail.

Electronics: Precision instruments and devices requiring non-magnetic, corrosion-resistant fasteners.

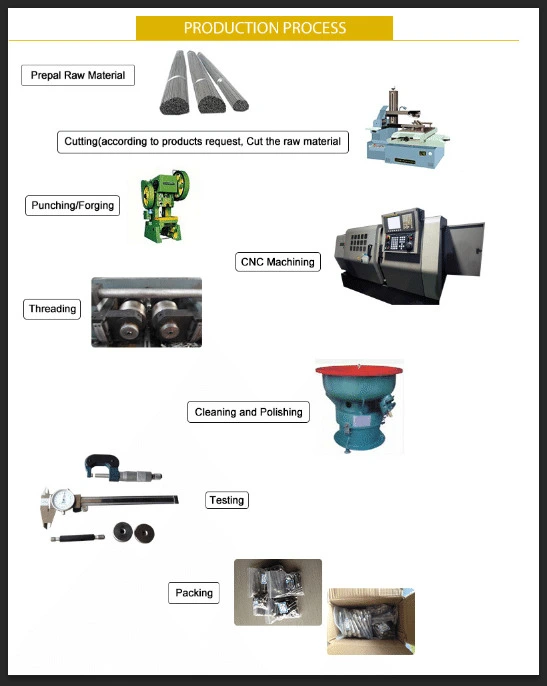

Manufacturing and Processing Capabilities

At Baoji Chuanglian, we utilize state-of-the-art CNC machining centers to produce your DIN34819 Titanium Torx Pan Head Tapping Screws with exceptional precision. Our manufacturing process includes cold heading, precision threading, and multiple quality checkpoints to ensure dimensional accuracy.

We maintain complete control over the production process, from raw material selection through final packaging. Our skilled technicians monitor every step to guarantee that each screw meets exact DIN34819 specifications. Custom modifications are available to meet your specific application requirements.

Production workshop

Production process

Our Services

Custom solutions, fast delivery, competitive pricing, and excellent service.

Titanium Product Manufacturing

Baoji Chuanglian New Metal Material Co., Ltd specializes in manufacturing high-quality titanium and rare metal products. With over ten years of experience, we produce titanium rods, plates, tubes, fasteners, and customized components. Our products meet strict national and international standards, ensuring durability and reliability. We cater to industries such as aerospace, medical, and petrochemical, providing high-performance titanium solutions tailored to customer needs.

Precision Titanium Machining

Equipped with advanced CNC machines, we offer precision machining services, including cutting, milling, drilling, and turning. Our experienced technicians ensure high accuracy and quality in every component. By continuously upgrading our technology, we meet complex machining demands for various industries. Whether you need standard titanium parts or custom-designed solutions, we provide efficient and reliable services.

Strict Quality Control

We maintain a rigorous quality control system from raw material selection to final inspection. Every product undergoes thorough testing to ensure superior performance and longevity. Our titanium products have been trusted by global companies for years, earning a reputation for reliability. With strict adherence to quality standards, we guarantee high-quality products with on-time delivery.

Global Titanium Solutions

Serving industries worldwide, we provide professional titanium solutions, from production to after-sales support. Our products are widely used in aerospace, medical, marine, and industrial fields. We focus on customer satisfaction, offering customized services and technical assistance. With a commitment to innovation and quality, we strive to build long-term partnerships and deliver high-value titanium products globally.

Be used in a wide range of industries.

Automotive Industry

Electronics Industry

Aerospace Industry

Medical Industry

Cars and Racing

Consumer Electronics

Why Choose Us?

Decades of Expertise

With over 10 years of experience, we deliver precise, high-quality titanium products tailored to industry standards.

Customized Solutions

We provide customized titanium solutions to meet your specific needs, ensuring optimal performance and satisfaction.

Advanced Technology

Our cutting-edge machinery ensures precise manufacturing, offering innovative and reliable titanium solutions.

Global Support

We offer excellent customer service, fast delivery, and reliable after-sales support worldwide.

Quality Assurance

Your satisfaction begins with our rigorous quality control system. We inspect raw materials upon arrival and conduct in-process monitoring throughout manufacturing. Each batch undergoes dimensional verification, torque testing, and surface finish evaluation.

Our quality management system ensures traceability from raw material to finished product. We provide material certifications and test reports upon request. This comprehensive approach has earned the trust of customers worldwide across multiple industries.

Packaging and Logistics

We package your screws in moisture-resistant containers to prevent contamination during shipping. Standard packaging includes plastic bags, cardboard boxes, or custom packaging based on your requirements. Each package includes clear labeling with part numbers, quantities, and material specifications.

Our logistics team coordinates worldwide shipping through reliable carriers. We offer flexible delivery options including express shipping for urgent orders. Bulk quantities receive special packaging attention to prevent damage during long-distance transport.

FAQ

Q: Can these screws be used in saltwater environments?

A: Yes, titanium's natural corrosion resistance makes these screws excellent for marine applications.

Q: What's the maximum torque specification?

A: Torque values depend on size and grade. We provide detailed torque charts with each order.

Q: Are custom lengths available?

A: Absolutely. We manufacture custom lengths to meet your specific application needs.

Q: How do these compare to stainless steel screws?

A: Titanium offers superior corrosion resistance and is 40% lighter than stainless steel while providing comparable strength.

Why Choose Us

With over ten years of titanium processing expertise, Baoji Chuanglian delivers consistent quality and reliable service. Our location in China's "City of Titanium" provides access to the finest raw materials and specialized manufacturing knowledge.

We combine advanced technology with skilled craftsmanship to produce DIN34819 Titanium Torx Pan Head Tapping Screws that exceed your expectations. Our commitment to continuous improvement ensures you receive the latest in titanium fastener technology.

Contact Us

Ready to experience superior titanium fastening solutions? Contact our technical team today for detailed specifications, custom quotes, or application assistance.

Email: info@cltifastener.com

Alternative Email: djy6580@aliyun.com

Our experts are standing by to help you select the perfect fastening solution for your next project.

Learn about our latest products and discounts through SMS or email