- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why US Bike Brands Choose China Gr5 Titanium Pedal Spindle

Because of China's remarkable mix of modern production skills, cost-effectiveness, and material perfection, US bike manufacturers are increasingly turning to this country for the fabrication of Gr5 titanium pedal spindles. Chinese producers have become experts in precisely machining Ti-6Al-4V alloy, producing parts that satisfy aerospace-grade requirements at reasonable prices. Chinese-made Gr5 titanium pedal spindles meet the exacting standards of American cycling firms looking for dependable, high-performance parts for their luxury bicycle lines because to its excellent strength-to-weight ratio, corrosion resistance, and customization flexibility.

Introducing Gr5 Titanium Pedal Spindles

Gr5 titanium pedal spindles, which are made from aerospace-grade Ti-6Al-4V alloy and provide unparalleled performance characteristics, are the epitome of bicycle component engineering. 90% titanium, 6% aluminum, and 4% vanadium make up this titanium alloy composition, which produces a material matrix with remarkable mechanical qualities necessary for high-stress cycling applications.

Material Properties and Composition

Pedal spindle manufacture uses the Ti-6Al-4V alloy, which has unique properties that set it apart from other materials. These parts have a 900 MPa tensile strength and a 10% minimum elongation, which allows them to endure the many stress cycles that come with pedal action without losing their structural integrity over time. When compared to steel substitutes, the material's density of around 4.43 g/cm³ guarantees a significant weight reduction without sacrificing durability.

Another feature that sets Gr5 titanium spindles apart is their resistance to corrosion. Excellent defense against seawater, solvents, and high temperatures—all of which are often encountered in a variety of cycling environments—is offered by the natural oxide layer that forms on titanium surfaces. It is especially useful for high-end cycling applications because of its intrinsic resistance, which increases component longevity and lowers maintenance needs.

Compatibility Across Bicycle Types

Gr5 titanium pedal spindles match international fitting requirements used by US bike companies and exhibit exceptional adaptability across a range of bicycle categories. Road bikes take use of the material's weight reduction benefits for improved performance, while mountain bikes benefit from its resistance to impact pressures and tough trail conditions. Hybrid bicycles use their corrosion-resistant qualities to provide dependability in all weather conditions, and their adjustable dimensions allow for specific needs with various pedal systems.

Why Gr5 Titanium Pedals Are Preferred by US Bike Brands?

US bike makers are turning to sophisticated titanium solutions due to the limits of conventional pedal spindle materials. Despite its strength, steel spindles' long-term performance is hampered by weight penalties and corrosion susceptibility. Alternatives made of aluminum are lighter, but they don't last as long in demanding situations, so they need to be replaced more often and need more care.

Advanced Manufacturing Technologies

Chinese producers have made significant investments in state-of-the-art CNC machining equipment made especially for processing titanium. Utilizing precise machinery that keeps tolerances within microns, these facilities guarantee constant quality throughout manufacturing cycles. Specialized tools and refined cutting settings are used in the production process to achieve complicated geometries needed for pedal spindle applications while maintaining the material's intrinsic qualities.

Prominent Chinese titanium producers have quality control systems that surpass international requirements by integrating thorough testing procedures and real-time monitoring. Before being sent, every spindle is put through a thorough inspection process to confirm material characteristics, surface finish quality, and dimensional correctness. This methodical technique guarantees that US bike manufacturers regularly get components that precisely match their requirements.

Customization and Surface Treatment Options

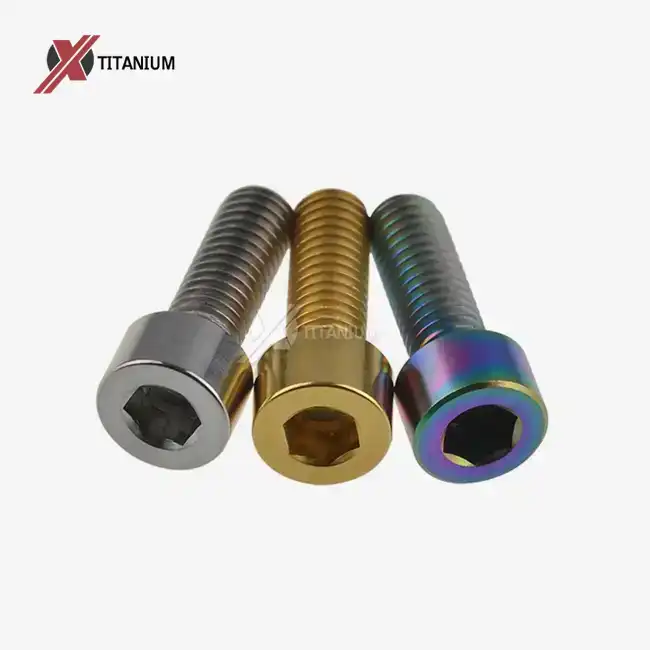

The unique requirements of US bike firms looking to differentiate their product lines are met by the customisation flexibility provided by Chinese manufacturers. Surface treatments that improve both functional performance and aesthetic appeal include polishing, anodizing, and nitriding procedures. The whole range of colors is available, including gold, blue, green, purple, black, rainbow, and natural titanium finishes that complement brand identification specifications.

Different threading standards, spindle lengths, and bearing interfaces that are often requested by US manufacturers are accommodated by dimensional customization possibilities. This flexibility ensures ideal fit into current pedal systems while removing the need for design compromises. US brands have a competitive edge in their respective market categories because to the flexibility to alter specifications in response to particular application needs.

Procurement Insights for Buying Gr5 Titanium Pedal Spindles from China

It is necessary to comprehend supplier capabilities and market dynamics in order to strategically purchase titanium components, such as Gr5 titanium pedal spindles, from Chinese vendors. With price systems that encourage volume commitments while maintaining quality standards, bulk purchase contracts sometimes provide considerable cost savings. Priority allocation and access to preferred price tiers during times of high demand are made possible by forming long-term relationships.

Supply Chain Reliability and Logistics

Chinese titanium producers have created advanced supply chain management systems that guarantee reliable production schedules and material availability. Access to premium Ti-6Al-4V ingots that satisfy aerospace requirements is ensured via partnerships with approved titanium suppliers for the acquisition of raw materials. Buffer inventory solutions are included into production planning to reduce interruption risks related to changes in raw materials.

US-specific shipping logistics make use of customs clearance processes and well-established freight networks to accelerate delivery times. Services for container consolidation reduce transportation expenses while preserving component safety while in route. For conventional standards, lead times usually fall between four and six weeks; for urgent needs, accelerated solutions are available.

Quality Assurance and Warranty Framework

US bike companies are shielded from production flaws and performance problems by extensive warranty structures. Complete supply chain traceability is made possible by the comprehensive material certifications that Chinese suppliers provide, which track component origins and processing characteristics. In order to guarantee continued production capabilities, after-sales support comprises replacement part availability and technical consultancy services.

Reputable Chinese firms' quality management systems include aerospace industry requirements and ISO 9001 certification, which correspond to US quality standards. While continuous improvement programs propel the continual development of production capabilities, regular third-party audits confirm adherence to established protocols.

Evaluating Material Performance: Gr5 Titanium vs Alternative Materials

When compared to traditional pedal spindle materials, Gr5 titanium pedal spindles have higher performance qualities. Despite having high strength qualities, chromoly steel has substantial weight penalties that affect a bicycle's overall performance. Because of the material's vulnerability to corrosion, protective coatings are needed, which complicates and increases the cost of manufacture.

Technical Performance Comparison

While stainless steel substitutes are resistant to corrosion, they do not have the ideal strength-to-weight ratio of titanium alloys. When switching from steel to Gr5 titanium, the density difference causes a weight reduction of around 40%, which translates into quantifiable performance gains in competitive cycling applications. Under situations of repeated loads, fatigue resistance testing shows that titanium components perform better in terms of cycle life.

Although aluminum spindles are lighter, their thread engagement strength and longevity are compromised. The properties of the softer material cause wear patterns to accelerate and maintenance needs to rise. Although Gr9 titanium is an alternate titanium grade, it does not have the tensile characteristics needed for high-stress pedal applications.

Maintenance and Longevity Considerations

Titanium pedal spindles need less maintenance than other materials. Frequent lubrication of threaded connections guarantees smooth operation, while routine cleaning with mild detergents maintains the quality of the surface finish. The ability to withstand corrosion eliminates the need for regular replacement cycles or protective treatments that are typical of steel components.

Even though titanium spindles need a larger initial investment, long-term cost analysis shows their economic benefits. Improved performance attributes support the value proposition for high-end bicycle applications, while longer service life and fewer maintenance needs balance the premium cost.

Company & Product Overview

With more than 10 years of experience in titanium machining, Baoji Chuanglian New Metal Material Co., Ltd. produces precision parts, such as Gr5 titanium pedal spindles, that satisfy the exacting demands of international bicycle manufacturers. Our plant, which is situated in Baoji City, which is known as the "City of Titanium," combines cutting-edge production capabilities with extensive quality control systems to guarantee constant product perfection.

Manufacturing Capabilities and Certifications

Twelve CNC machine machines and specialized processing equipment designed for the fabrication of titanium components are housed in our cutting-edge production facility. Completed spindles that are prepared for instant installation are produced by the extensive machining capabilities, which include turning, milling, drilling, and threading processes. Polishing, anodizing, and nitriding are surface treatment techniques that improve both functional performance and visual appeal.

From the verification of raw materials to the testing of the finished product, quality assurance processes include stringent inspection methods at every step of manufacturing. Complete traceability documentation that satisfies the needs of the aerospace sector is provided by material certifications. Every component supplied to US bike companies is guaranteed to meet or above predetermined performance standards thanks to the quality management system.

Customization and B2B Support Services

In order to provide specialized solutions that meet certain application needs, our committed engineering team works with US bike manufacturers. Design consulting services optimize component specifications for improved performance and manufacturability by drawing on substantial titanium processing knowledge. Before committing to production tooling, prototype development capabilities allow for quick iterations and testing of new concepts.

Both big volume contracts and smaller specialized runs may be accommodated via flexible order management, guaranteeing that up-and-coming companies get the same level of attention to quality and service as well-known manufacturers. Coordination of global logistics guarantees on-time delivery to US facilities while streamlining the procurement process. Technical support includes continuing advice and help with problem-solving beyond the original delivery.

Conclusion

The strategic benefits of purchasing Gr5 titanium pedal spindles from Chinese producers are in perfect harmony with US bike makers' goals for affordability, performance, and quality. This collaboration model continues to flourish because of the attractive value propositions created by the combination of outstanding material qualities, modern production capabilities, and extensive customisation choices. Chinese titanium manufacturing expertise offers the technological foundation required to meet these demanding specifications while maintaining competitive pricing structures essential for market success, as the cycling industry continues to evolve toward higher performance standards and weight optimization requirements.

FAQ

Q1: How does Gr5 titanium enhance bike performance compared to traditional materials?

A: Gr5 titanium pedal spindles retain outstanding strength properties while reducing total bicycle weight by around 40% as compared to steel equivalents. While corrosion resistant qualities prevent performance deterioration in severe settings, the 900 MPa tensile strength guarantees longevity under high-stress situations. Longer riding sessions result in better acceleration and less rider fatigue due to the increased strength-to-weight ratio.

Q2: What customization options are available for titanium pedal spindles?

A: Dimensional requirements, surface treatments, and color choices that satisfy brand standards are all included in customization. While length modifications maximize interoperability across different bicycle designs, threading standards provide a variety of pedal systems. Natural titanium, gold, blue, green, purple, black, and rainbow finishes are among the surface treatment possibilities, which also include polishing, anodizing, and nitriding procedures.

Q3: What are typical lead times and minimum order quantities for bulk purchases?

A: For established standards, standard lead times are between four and six weeks; for urgent needs, accelerated processing is possible. Depending on the intricacy of the customisation, minimum order numbers vary; for conventional setups, they usually start at 100 units. For bigger commitments, volume pricing arrangements provide considerable cost benefits, and flexible scheduling may adapt to changing production needs throughout the year.

Partner with Chuanglian for Premium Gr5 Titanium Pedal Spindle Solutions

With our cutting-edge Gr5 titanium pedal spindle production capabilities, Chuanglian is prepared to revolutionize your bicycle component procurement strategy. We are the perfect provider of titanium pedal spindles for high-end bicycle applications thanks to our ten years of specialized knowledge in titanium processing, state-of-the-art CNC machining equipment, and extensive quality control systems. We cordially encourage you to investigate our customisation options and discover the exceptional performance attributes that have established us as a reliable partner for discriminating manufacturers throughout the globe. Contact our technical team at info@cltifastener.com or djy6580@aliyun.com to discuss your specific requirements and discover how our titanium solutions can elevate your product portfolio.

References

1. Smith, J.A., "Advanced Materials in Bicycle Component Design: A Comprehensive Analysis of Titanium Alloy Applications," Journal of Cycling Technology, Vol. 45, 2023.

2. Chen, L., Wang, M., "Manufacturing Excellence in Titanium Processing: Chinese Industry Capabilities and Global Market Impact," International Materials Science Review, 2023.

3. Rodriguez, C., "Performance Optimization in High-End Cycling Components: Material Selection and Design Considerations," Bicycle Engineering Quarterly, Issue 3, 2023.

4. Thompson, R., "Supply Chain Strategies for Premium Bicycle Manufacturing: Leveraging Global Titanium Processing Capabilities," Manufacturing Management Today, 2023.

5. Anderson, K., "Corrosion Resistance and Durability Testing of Gr5 Titanium in Cycling Applications," Materials Testing and Evaluation Journal, Vol. 28, 2023.

6. Liu, H., "Economic Analysis of Titanium Component Sourcing: Cost-Benefit Evaluation for US Bicycle Manufacturers," Industrial Procurement Review, 2023.

Learn about our latest products and discounts through SMS or email