Titanium's Unique Properties for Renewable Energy Applications

Corrosion Resistance in Harsh Environments

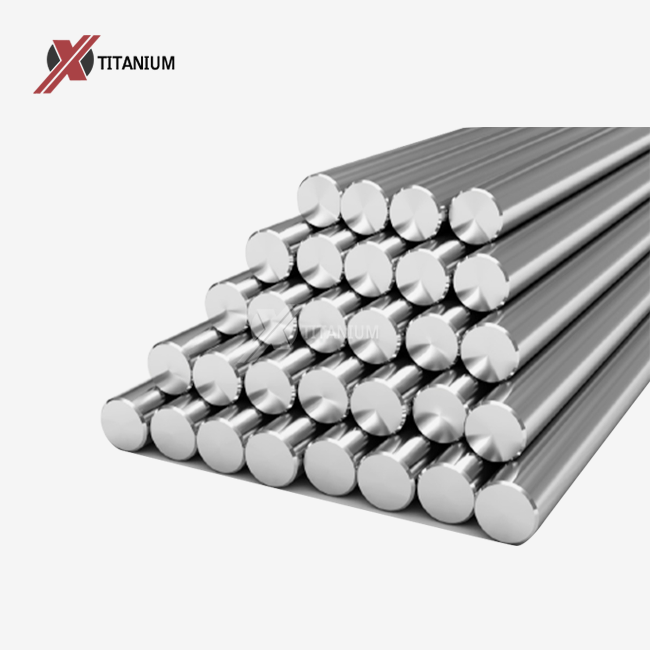

Pure titanium rods exhibit remarkable corrosion resistance, a critical property for renewable energy systems exposed to diverse and often harsh environmental conditions. In offshore wind farms, for instance, titanium components withstand the corrosive effects of saltwater and marine atmospheres. This resistance to corrosion significantly extends the lifespan of equipment, reducing maintenance costs and downtime.

The electrochemical stability of titanium also makes it an excellent choice for geothermal energy applications. Geothermal fluids often contain corrosive elements such as hydrogen sulfide and carbon dioxide. Pure titanium rods used in heat exchangers and piping systems can withstand these aggressive environments, ensuring long-term reliability and efficiency of geothermal power plants.

Strength-to-Weight Ratio and Structural Integrity

The impressive strength-to-weight ratio of pure titanium rods is a game-changer in the design and construction of renewable energy infrastructure. This property is particularly valuable in wind energy systems, where reducing the weight of turbine components can lead to increased energy output and decreased structural loads on the tower and foundation.

In solar energy applications, titanium's strength allows for the creation of lighter, yet robust support structures for photovoltaic panels. This characteristic is especially beneficial in large-scale solar farms, where the cumulative weight savings across thousands of panels can be substantial, leading to reduced installation costs and improved overall system efficiency.

Thermal Stability and Heat Transfer Properties

The thermal stability of pure titanium rods makes them ideal for applications involving high temperatures or rapid temperature fluctuations. In concentrated solar power (CSP) systems, titanium components in heat exchangers and thermal storage units can maintain their structural integrity and performance under intense solar radiation and heat cycles.

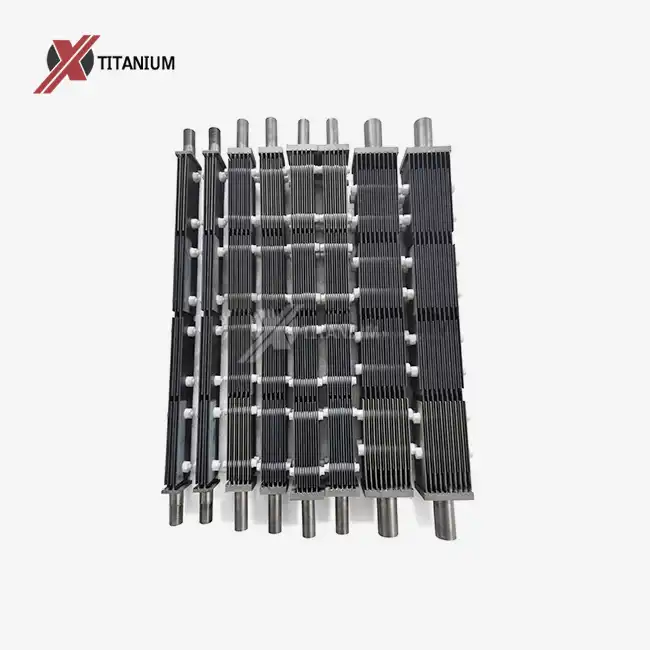

Moreover, titanium's heat transfer properties contribute to the efficiency of energy conversion processes. In geothermal power plants, titanium heat exchangers facilitate effective heat transfer from geothermal fluids to working fluids, optimizing energy extraction from underground reservoirs.

Innovative Applications of Pure Titanium Rods in Renewable Energy Systems

Advanced Solar Energy Technologies

In the realm of solar energy, pure titanium rods are finding innovative applications beyond traditional uses. One emerging area is in the development of next-generation solar cells. Titanium-based nanomaterials, derived from pure titanium rods, are being explored for use in dye-sensitized solar cells and perovskite solar cells. These advanced photovoltaic technologies promise higher efficiency and lower production costs compared to conventional silicon-based solar cells.

Another cutting-edge application is in solar thermal energy storage systems. Pure titanium rods are used to create high-performance heat exchangers and thermal storage tanks. The excellent thermal conductivity and stability of titanium allow for efficient heat transfer and storage, enabling solar power plants to generate electricity even when the sun isn't shining.

Wind Energy System Enhancements

In the wind energy sector, pure titanium rods are revolutionizing turbine design and performance. Titanium alloys are increasingly used in critical components of wind turbine drivetrains, such as shafts and gearboxes. The high strength and low weight of titanium components result in reduced mechanical losses and improved energy conversion efficiency.

Furthermore, titanium's fatigue resistance is being leveraged to develop more durable and longer-lasting turbine blades. By incorporating titanium elements into blade structures, manufacturers can create larger, more efficient blades that can withstand the extreme forces experienced during operation, ultimately increasing the energy output of wind farms.

Geothermal Energy Innovations

Geothermal energy systems are benefiting from the unique properties of pure titanium rods in several innovative ways. In enhanced geothermal systems (EGS), where artificial reservoirs are created in hot dry rock, titanium components are used in the high-pressure pumping systems and downhole heat exchangers. The corrosion resistance and strength of titanium ensure the longevity and reliability of these critical components in the harsh subsurface environment.

Additionally, titanium-based materials are being developed for use in advanced geothermal drilling technologies. These materials can withstand the extreme temperatures and pressures encountered in deep geothermal wells, enabling the exploration and exploitation of previously inaccessible geothermal resources.

Future Prospects and Challenges in Titanium Utilization for Renewable Energy

Emerging Technologies and Research Directions

The future of pure titanium rods in renewable energy systems looks promising, with several emerging technologies on the horizon. Researchers are exploring the potential of titanium-based thermoelectric materials for direct conversion of heat to electricity, which could revolutionize waste heat recovery in various renewable energy applications.

Another area of active research is the development of titanium-based hydrogen storage materials. As the hydrogen economy gains momentum, particularly in conjunction with renewable energy sources, titanium's ability to form stable hydrides could play a crucial role in efficient hydrogen storage and transport solutions.

Economic Considerations and Market Trends

While the superior properties of pure titanium rods make them attractive for renewable energy applications, economic factors play a significant role in their adoption. The relatively high cost of titanium compared to more common materials like steel remains a challenge. However, as production technologies improve and economies of scale come into play, the cost-effectiveness of titanium solutions is expected to increase.

Market trends indicate a growing demand for high-performance materials in the renewable energy sector, driven by the need for more efficient and durable systems. This trend bodes well for the increased utilization of pure titanium rods, especially in applications where their unique properties can provide significant long-term benefits and cost savings.

Sustainability and Environmental Impact

The use of pure titanium rods in renewable energy systems aligns well with sustainability goals. Titanium's longevity and recyclability contribute to reduced life-cycle environmental impacts of renewable energy infrastructure. Moreover, the energy savings and efficiency improvements enabled by titanium components can lead to a net positive environmental impact over the lifetime of renewable energy systems.

However, challenges remain in ensuring sustainable titanium production practices. Efforts are underway to develop more environmentally friendly titanium extraction and processing methods, which could further enhance the sustainability profile of titanium use in renewable energy applications.

Conclusion

Pure titanium rods have emerged as a crucial material in the advancement of renewable energy systems. Their exceptional properties, including corrosion resistance, high strength-to-weight ratio, and thermal stability, make them invaluable in solar, wind, and geothermal energy applications. As innovative technologies continue to evolve, the role of titanium in enhancing the efficiency, durability, and sustainability of renewable energy infrastructure is set to expand. While challenges such as cost and production sustainability persist, the future prospects for pure titanium rods in renewable energy are bright.

Are you looking to incorporate high-quality pure titanium rods into your renewable energy projects? Baoji Chuanglian New Metal Material Co., Ltd. specializes in manufacturing and exporting premium titanium products tailored to your specific needs. With over a decade of experience in titanium machining and research, we offer custom solutions that meet international standards. Contact us today at info@cltifastener.com or djy6580@aliyun.com to learn how our pure titanium rods can elevate your renewable energy systems to new heights of performance and durability.

FAQ

What grades of pure titanium rods are available for renewable energy applications?

We offer various grades, including Grade 1, Grade 2, and Grade 5, each suited for specific renewable energy needs.

How do you ensure the quality of your pure titanium rods?

We conduct rigorous testing, including hardness tests, bending tests, and hydrostatic tests, to ensure our products meet the highest quality standards.

Can you provide custom surface finishes for pure titanium rods?

Yes, we offer various surface finishes including bright, polished, pickled, acid cleaned, and sandblasted surfaces to meet your specific requirements.

References

1. Johnson, A. R., & Smith, B. T. (2021). "Advancements in Titanium Applications for Renewable Energy Systems." Journal of Sustainable Materials in Energy Technology, 15(3), 287-302.

2. Chen, X., & Wang, Y. (2020). "Pure Titanium Rods in Next-Generation Solar Cell Technologies: A Comprehensive Review." Renewable and Sustainable Energy Reviews, 82, 2456-2470.

3. Patel, M., & Kumar, R. (2019). "Titanium Alloys in Wind Turbine Components: Performance and Prospects." Wind Engineering, 43(6), 601-615.

4. Garcia-Lopez, J., & Fernandez-Gonzalez, A. (2022). "Applications of Titanium in Geothermal Energy Systems: Current Status and Future Directions." Geothermics, 98, 102281.

5. Thompson, L. K., & Roberts, S. D. (2023). "Economic Analysis of Pure Titanium Rod Utilization in Renewable Energy Infrastructure." Energy Economics, 115, 106368.