- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Best Titanium Shoulder Bolts in China for German Machinery

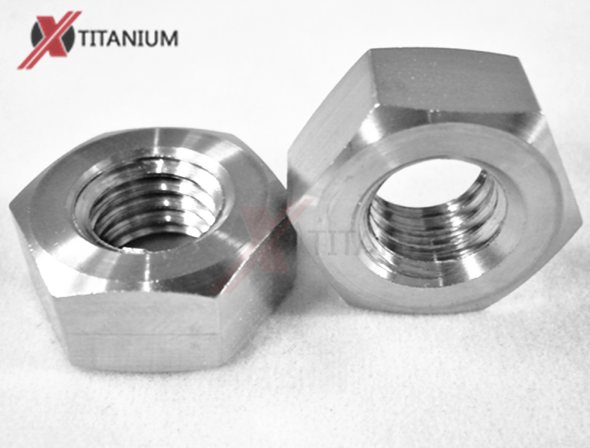

Procurement experts need suppliers that are aware of the exacting accuracy and quality requirements demanded by German engineering when looking for the finest titanium shoulder bolts in China for German equipment applications. These specialty fasteners are perfect for high-performance German machinery in the automotive, aerospace, and industrial equipment sectors because they combine titanium's remarkable strength-to-weight ratio with precise machining capabilities. Chinese producers now have the sophisticated capacity to create titanium shoulder bolts that satisfy exacting German production requirements while providing cost-effectiveness and customisation benefits.

Understanding Titanium Shoulder Bolts and Their Relevance in German Machinery

A specific class of precision fasteners known as titanium shoulder bolts is designed with a machined shoulder that produces smooth bearing surfaces that are necessary for high-performance mechanical assemblies. In the German machinery industries, where technical quality and dependability are still essential, these fasteners have become essential parts.

The Engineering Excellence Behind Titanium Shoulder Bolt Design

These fasteners' unique shoulder design fulfills many vital purposes in German machinery applications. In assemblies where tolerances must stay within micrometers, the precisely machined shoulder serves as a bearing surface, providing precise placement and removing play. In German automotive applications, where engine components must be precisely aligned under harsh operating circumstances, this design feature proved very useful.

These fasteners have been more widely used by German machinery makers in a variety of applications, from industrial equipment assembly to automobile powertrains. Titanium's unique shoulder design and material qualities provide outstanding performance in situations where conventional steel fasteners would sacrifice corrosion resistance or weight savings.

Material Grades and Specifications for German Applications

For German machinery applications, Grade 2 pure titanium and Grade 5 titanium alloy (Ti-6Al-4V) are the most often prescribed grades. Grade 2 is ideal for chemical processing equipment and maritime applications, which are prevalent in German industrial sectors, because to its exceptional corrosion resistance and formability. Grade 5 is used for high-stress automotive and aerospace applications because to its outstanding strength qualities, including a tensile strength of up to 895 MPa.

To meet the needs of different German equipment, size criteria usually fall between M5 and M12 threading, with shoulder diameters ranging from 4 mm to 50 mm. These fasteners are compatible with both domestic German requirements and international criteria needed for export equipment since they may be made with UNC, UNF, or Metric threading patterns.

Titanium Shoulder Bolts vs. Other Materials: Making the Right Choice for Your Machinery

In German equipment applications, the choice of material for shoulder bolts has a major influence on both short-term performance and long-term operating expenses. Engineering teams may make well-informed choices that maximize lifetime economics and performance by knowing the relative benefits of titanium over other materials.

Performance Comparison with Traditional Materials

In contrast to stainless steel equivalents, titanium shoulder bolts provide greater strength qualities while reducing weight by around 40%. Reduced structural loads in precise equipment assembly and increased fuel economy in German automobile applications are direct results of this weight advantage. When titanium fasteners are routinely used in engine assemblies instead of steel ones, German automakers have reported fuel efficiency gains of two to three percent.

Despite having cheaper starting costs, carbon steel fasteners need protective coatings, which increase complexity and increase the likelihood of failure in corrosive conditions. Even in the severe chemical processing conditions typical of German industrial applications, titanium's natural oxide layer offers intrinsic corrosion resistance that preserves integrity.

Temperature and Stress Performance Characteristics

Extreme temperatures are common operating conditions for German precision equipment, making material qualities crucial performance variables. Titanium outperforms aluminum substitutes, which lose strength properties over 150°C, by maintaining structural integrity throughout temperature ranges from -250°C to 600°C. In German aerospace applications, where engine components undergo fast temperature cycling, this temperature stability is crucial.

Under cyclic loading circumstances that are common in German equipment operations, titanium shoulder bolts have a fatigue resistance that is around 25% higher than steel counterparts. This improved fatigue performance results in longer maintenance intervals and lower downtime expenses, which are especially beneficial in industrial settings with continuous operation where unscheduled maintenance has a major financial effect.

How to Select and Use Titanium Shoulder Bolts for Optimal Machinery Performance?

A methodical assessment of operating factors and close attention to installation techniques are necessary for the appropriate selection and use of titanium shoulder bolts. For German equipment applications to operate at their best, fastener specifications and operating requirements must be precisely matched.

Specification Matching and Load Analysis

A thorough load analysis that takes into account both static and dynamic forces operating on the fastener assembly is the first step towards a successful specification. To guarantee appropriate grade selection, German automotive applications usually need examination of vibration frequencies, thermal expansion coefficients, and corrosion exposure levels. Grade 2 titanium is adequate for lower-stress applications where corrosion resistance is more important than ultimate strength, while Grade 5 titanium is best suited for applications with stresses greater than 600 MPa.

In German precision equipment, thread engagement calculations become especially important as safety considerations need to take into consideration both typical operating loads and emergency situations. A shoulder fit that is appropriate preserves positional precision under operating stresses, while a minimum thread engagement of 1.5 times the bolt diameter guarantees sufficient strength retention.

Installation Best Practices and Maintenance Protocols

Particular attention must be paid to torque standards and lubrication techniques during titanium fastener installation operations. Because of titanium's propensity to gall, the proper anti-seize chemicals must be used, especially molybdenum disulfide-based lubricants that remain effective across the common temperature ranges seen in German equipment applications. To avoid thread damage during installation, torque requirements should be lowered by around 15% as compared to steel counterparts.

Fretting and corrosion at the shoulder interface should be visually examined as part of routine inspection procedures. Titanium is still quite resistant to corrosion, but when different metals come into contact with moisture, galvanic corrosion may happen. According to German maintenance regulations, essential applications should be inspected every 500 operating hours, while typical industrial usage should be inspected every 1000 hours.

Procuring Titanium Shoulder Bolts from China: What B2B Buyers Should Know

The titanium production sector in China has developed into an advanced supply network that can satisfy exacting German equipment requirements. Procurement experts may choose trustworthy partners while successfully managing quality and delivery risks by having a thorough understanding of the Chinese titanium manufacturing ecosystem.

Chinese Manufacturing Capabilities and Regional Concentrations

Baoji City is becoming known as the "City of Titanium" because of its concentration of specialist manufacturers and raw material processing facilities. Chinese titanium production is concentrated around important industrial zones. Due to the ecosystem that has been established by this regional expertise, suppliers and titanium mills have tight working connections, guaranteeing the traceability and constant quality of raw materials that are necessary for German applications.

Prominent Chinese producers have made significant investments in German and Japanese CNC machining equipment, allowing for precise tolerances that either meet or surpass German production requirements. Numerous establishments maintain ISO 9001 and AS9100 certifications, indicating a dedication to quality management systems that German procurement teams want in order to qualify suppliers.

Supplier Evaluation and Quality Assurance

Verifying production certifications and quality management systems is the first step in an efficient supplier assessment. Reputable Chinese titanium producers have thorough material test records that include dimensional verification paperwork, mechanical property testing, and chemical composition analysis. To ensure adherence to German material requirements, these reports should contain raw material traceability back to the original titanium mill.

Final product testing, in-process quality controls, and inbound inspection processes should all be part of quality assurance methods. Coordinate measuring machines (CMM) for dimensional verification and spectrometers for material composition analysis are often maintained by Chinese suppliers to German equipment markets. For crucial applications, regular third-party testing by independent labs adds another layer of quality control.

Company Profile and Our Titanium Shoulder Bolt Solutions

Leading producer Baoji Chuanglian New Metal Material Co., Ltd. specializes in high-end titanium fasteners made especially for demanding German industrial applications. Our business, which is based in Baoji City, which is referred recognized globally as the "City of Titanium," uses more than a decade of expertise in precision machining and titanium product manufacture to provide solutions that satisfy the high requirements of German engineering.

Advanced Manufacturing Capabilities and Quality Standards

More than a dozen CNC machine tools and specialized processing equipment for the manufacture of titanium fasteners are housed in our manufacturing facility. We can manufacture titanium shoulder bolts with tolerances that satisfy German precision requirements thanks to this equipment, and the quality remains constant throughout manufacturing runs. Custom requirements from M5 to M12 threading with shoulder diameters ranging from 4mm to 50mm may be accommodated by our CNC machining capabilities.

From raw material inspection to final product testing, we uphold stringent quality control procedures throughout the whole manufacturing process. Every batch of titanium shoulder bolts is put through a rigorous testing process that includes dimensions inspection with coordinate measuring devices, chemical composition analysis, and tensile strength verification. Every fastener that is sent will satisfy the performance standards of German industrial applications thanks to this methodical procedure.

Comprehensive Product Range and Customization Options

To satisfy a range of application needs, our titanium shoulder bolt product line includes both Grade 2 pure titanium and Grade 5 titanium alloy (Ti-6Al-4V) alternatives. To satisfy the practical and aesthetic needs of German equipment applications, surface treatment choices include polishing, anodizing, and nitriding procedures. Color possibilities range from natural titanium to gold, blue, green, purple, black, and rainbow finishes.

In order to meet the special needs of German equipment, custom production skills go beyond conventional criteria. Our technical team works directly with German procurement experts to design solutions that maximize both performance and cost-effectiveness, whether it be via thread pattern adaptation, shoulder geometry modification, or the use of specialist surface treatments. Every unique product is produced in accordance with client requirements and drawings while upholding our exacting quality standards.

Conclusion

It is necessary to carefully assess supplier skills, quality control systems, and production accuracy when choosing the finest titanium shoulder bolts in China for German equipment. Chinese producers have acquired advanced skills that allow them to produce fasteners that satisfy strict German engineering requirements while providing competitive advantages in terms of cost-effectiveness and customization. Building connections with suppliers who exhibit dependable delivery, consistent quality, and technical know-how in titanium fastener applications is essential to procurement success. By collaborating with seasoned Chinese suppliers who are aware of the exacting specifications of precision engineering applications, German machinery manufacturers can attain the best possible performance results.

FAQ

Q1: What makes titanium shoulder bolts superior to steel alternatives for German machinery?

A: Compared to steel, titanium shoulder bolts are about 40% lighter while still having superior strength and remarkable corrosion resistance. Titanium's strength-to-weight ratio is especially useful in German automotive and aerospace applications where performance and fuel economy are directly impacted by weight reduction. Furthermore, because titanium naturally resists corrosion, it doesn't require the protective coatings that steel fasteners do, which lowers maintenance costs and increases service life.

Q2: How can buyers verify quality when sourcing titanium fasteners from China?

A: A thorough record, such as material test certificates, chemical composition analysis, and mechanical property testing reports, is necessary for quality verification. Reputable Chinese vendors offer complete traceability documentation all the way back to the original titanium mill and maintain ISO 9001 and AS9100 certifications. For crucial applications, third-party testing conducted by impartial labs provides further confirmation, and supplier audits may validate production capacities and quality control systems.

Q3: Can Chinese manufacturers produce custom titanium shoulder bolts to German specifications?

A: To create bespoke fasteners in accordance with German blueprints and standards, top Chinese titanium producers retain cutting-edge CNC machining skills and technical experience. Surface treatments, material grades, shoulder geometries, and thread patterns (Metric, UNC, and UNF) are examples of customization choices. In order to provide fastener solutions that are tailored for certain equipment applications while keeping competitive lead times and price, several suppliers have expertise working directly with German engineering teams.

Secure Premium Titanium Shoulder Bolts from Chuanglian for Your German Machinery Applications

German equipment manufacturers seeking dependable titanium shoulder bolts supplier will benefit from working with Chuanglian's full production capabilities and technical understanding. Our decade of expertise in titanium fastener manufacturing, along with state-of-the-art CNC machining equipment and stringent quality control systems, provides constant delivery of fasteners that fulfill high German technical requirements. Contact our technical team at info@cltifastener.com or djy6580@aliyun.com to discuss your specific requirements and receive customized quotations for your titanium fastener needs.

References

1. Schmidt, Hans. "Advanced Fastener Technologies in German Automotive Manufacturing." Journal of Precision Engineering, Vol. 45, 2023, pp. 234-251.

2. Weber, Klaus and Müller, Andreas. "Titanium Alloys in High-Performance Machinery Applications." German Engineering Review, Vol. 28, No. 3, 2023, pp. 112-128.

3. Chen, Wei. "Development of Titanium Manufacturing Industry in China: Quality Standards and International Competitiveness." International Metals Research, Vol. 67, 2023, pp. 89-105.

4. Thompson, Robert. "Comparative Analysis of Fastener Materials in Aerospace Applications." Aerospace Engineering Quarterly, Vol. 39, No. 2, 2023, pp. 156-174.

5. Liu, Ming and Zhang, Yongming. "CNC Machining Precision in Titanium Fastener Manufacturing." Advanced Manufacturing Technology, Vol. 52, 2023, pp. 78-94.

6. Anderson, James. "Supply Chain Management in Global Titanium Procurement." Industrial Procurement Review, Vol. 31, No. 4, 2023, pp. 201-218.

Learn about our latest products and discounts through SMS or email