- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Where US Buyers Source Titanium Shoulder Bolts in China

Chinese producers are becoming more and more popular among US consumers looking for premium titanium shoulder bolts. China has become a major player in the titanium processing industry by providing affordable options without sacrificing quality requirements. The nation is a desirable sourcing location for the aerospace, automotive, marine, and medical sectors that need specific fasteners because of its sophisticated production capabilities, reasonable price, and adherence to international standards.

Understanding Titanium Shoulder Bolts and Their Applications

A specific class of well designed fasteners that combine remarkable mechanical qualities with adaptable functionality are titanium shoulder bolts. These parts are essential in applications needing precise dimensional control and high performance characteristics because of their unique cylindrical shoulder portion, which doubles as a bearing surface and accurate positioning element.

Material Composition and Grades

Grade 2 pure titanium and Grade 5 titanium alloy (Ti-6Al-4V) are the most widely obtained grades, and each has unique benefits for certain uses. Grade 2 titanium is perfect for maritime and medical applications because of its exceptional biocompatibility and resistance to corrosion. Superior strength-to-weight ratios are provided by grade 5 titanium alloy, which is around 40% lighter than steel counterparts and has a tensile strength of up to 895 MPa while retaining a density of just 4.43 g/cm³.

Critical Applications Across Industries

These fasteners are used by aerospace manufacturers in landing gear systems, engine assembly, and wing structures where weight reduction has a direct influence on operating costs and fuel efficiency. For high-performance aircraft applications, titanium's remarkable temperature resistance enables these bolts to retain structural integrity at temperatures beyond 400°C.

Because titanium shoulder bolts are non-magnetic and biocompatible, medical device makers use them for surgical tools and implanted devices. The material is very useful for orthopedic applications because of its resistance to physiological fluids and capacity to integrate with bone tissue.

Titanium's exceptional corrosion resistance is advantageous to the marine and chemical processing sectors, especially in saltwater settings where conventional steel fasteners would deteriorate quickly. In challenging working environments, these bolts can endure exposure to very corrosive substances and retain their mechanical qualities.

Why US Buyers Source Titanium Shoulder Bolts from China?

Few nations can match China's production capacity, cost effectiveness, and technical advancements, which account for its dominance in the titanium fastener market. The country has made significant investments in building advanced production facilities especially for titanium processing, giving it a competitive edge that goes beyond straightforward cost concerns.

Cost Advantages and Manufacturing Scale

While keeping the same level of quality, Chinese manufacturers usually provide prices that are 20–40% less than those of similar US or European vendors. Optimized production procedures, effective supply chain management, and economies of scale attained via high-volume manufacturing capabilities all contribute to this cost advantage.

Known as the "Titanium Valley of China," the concentration of titanium processing facilities in areas like Baoji City fosters a cooperative atmosphere where manufacturers, suppliers, and research institutes work together to promote efficiency and innovation. In addition to lowering the cost of material transportation, this spatial clustering facilitates quick information sharing among industry players.

Quality Certifications and Standards Compliance

Prominent Chinese producers uphold strict quality control procedures that adhere to global norms, such as FDA regulations for medical devices, ISO 9001 for general production, and AS9100 for aerospace applications. Numerous facilities have shown their capacity to fulfill the strictest quality standards by obtaining NADCAP accreditation for unique procedures.

Coordinate measuring devices with accuracy levels greater than ±0.005mm are used for dimensional inspection, mechanical property verification, and chemical composition analysis, among other advanced testing capabilities. These quality control procedures guarantee that goods fulfill or surpass the requirements set by exacting US industry.

Supply Chain Infrastructure and Logistics

Effective transportation from production facilities to international shipping ports is made possible by China's sophisticated logistics network. Lead times of 2-4 weeks for conventional orders and 4-6 weeks for special configurations are made possible by major titanium production facilities' strategic proximity to shipping hubs.

For just-in-time production settings, which are prevalent in the automotive and aerospace sectors, the integration of digital tracking systems addresses supply chain transparency problems by offering real-time insight into order status and shipping progress.

How to Choose the Right Chinese Supplier for Titanium Shoulder Bolts?

Beyond simple price comparisons, choosing a reliable Chinese source for titanium shoulder bolts requires a methodical assessment process. owing diligence is necessary to guarantee supplier competence and dependability owing to the intricacy of titanium processing and the vital nature of applications where these fasteners are used.

Certification and Quality System Evaluation

Potential providers have to exhibit adherence to pertinent industry certifications unique to the sector in where you are using your product. While ISO 13485 conformity is required for medical applications, AS9100 certification is required for aerospace uses. Throughout the production cycle, manufacturing facilities should have traceability systems in place that monitor the origin of materials, processing parameters, and quality test results.

Request comprehensive documentation, such as process qualification records, dimensional inspection reports, and material test certifications. Reputable vendors are happy to provide this information and may use facility audits or independent evaluations to show off their quality management systems.

Manufacturing Capabilities Assessment

Examine the supplier's machining skills, paying special attention to the CNC equipment and tooling requirements. To achieve the necessary surface finishes and dimensional tolerances, titanium processing calls for specialized cutting tools and precise machining settings. Experience with different surface treatments, including as polishing, anodizing, and nitriding procedures, should be shown by suppliers.

For applications that need for unique features or non-standard dimensions, custom manufacturing expertise is crucial. Seek for vendors that can handle several thread types, such as metric, UNC, and UNF configurations, and shoulder sizes between 4 and 50 mm.

Technical Support and Engineering Services

Reputable vendors provide thorough technical assistance, which includes advice on material selection, suggestions for design optimization, and consulting services tailored to a particular application. When creating new goods or refining current designs for better performance or cost effectiveness, this knowledge becomes very important.

Prototype development services for product validation prior to full-scale manufacturing, material property databases for application-specific selection, and finite element analysis capabilities for stress optimization are all examples of engineering assistance.

Procurement Best Practices for US Buyers Importing Titanium Shoulder Bolts from China

Effective procurement methods must minimize the risks associated with managing an international supply chain while addressing the particular difficulties involved in importing specialist titanium shoulder bolts. Buyers that are successful create all-encompassing strategies that take logistical, technical, and business factors into account.

Sample Evaluation and Qualification Process

Start each new supplier connection with a comprehensive approach for evaluating samples. Ask for examples that accurately reflect your needs, taking into account the material quality, size, surface polish, and other unique characteristics. Verify material qualities independently using third-party testing to confirm supplier claims and guarantee that your criteria are being met.

Clearly define acceptance criteria, such as mechanical property requirements, surface polish parameters, and dimensional tolerances. These needs should be documented in comprehensive procurement specifications that remove any doubt and provide impartial assessment criteria.

Contract Negotiation and Risk Management

Create thorough supplier agreements that include delivery dates, quality standards, packaging details, and inspection protocols. Incorporate clauses pertaining to material traceability, requirements for certificates of compliance, and processes for correcting non-conforming goods.

Think of introducing phased payment conditions that link remuneration to quality acceptance and delivery milestones. This strategy offers power to guarantee compliance while preserving good connections with suppliers.

Import Compliance and Documentation

Costly delays and compliance problems may be avoided by being aware of import laws and paperwork requirements. Depending on their intended use, titanium items may be subject to certain import taxes or legal constraints. Work with seasoned freight forwarders who can expedite customs clearance and who are knowledgeable with titanium import requirements.

Keep thorough records of every import transaction, including packing lists, test certifications, commercial invoices, and customs paperwork. This paperwork becomes crucial for auditing reasons and makes it easier to handle orders in the future.

Chuanglian: Your Trusted Partner for Premium Titanium Shoulder Bolts

With more than 10 years of specialized expertise in titanium processing and machining, Baoji Chuanglian New Metal Material Co., Ltd. is a leading producer of quality titanium fasteners, including titanium shoulder bolts. Our enterprise, which is situated in Baoji City, often known as the "City of Titanium," is at the center of China's titanium industrial cluster and has unmatched access to technological know-how and raw resources.

Advanced Manufacturing Capabilities

Several CNC machining facilities with specialized equipment tailored for titanium processing are located inside our facility. We provide shoulder bolts in M5 to M12 sizes, with bespoke dimensions available to satisfy certain application needs. Our threading possibilities include metric, UNC, and UNF combinations, and shoulder diameters ranging from 4mm to 50mm meet a variety of industrial demands.

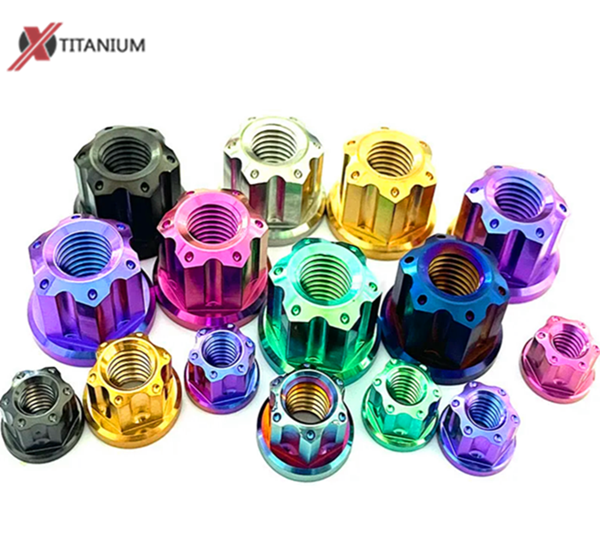

Polishing, anodizing, and nitriding techniques are among the surface treatment choices. Natural titanium, gold, blue, green, purple, black, and rainbow finishes are among the color variants. In addition to improving visual appeal, these treatments provide more wear resistance and corrosion protection for demanding applications.

Quality Assurance and Certification

From raw material inspection to final product verification, our quality management system guarantees strict supervision throughout the production process. To ensure adherence to client requirements, every batch is put through a rigorous testing process that includes dimensional inspection, mechanical property verification, and chemical composition analysis.

We keep comprehensive traceability records for every product, making it possible to fully document the origin of the materials and the processing history. Applications in the aerospace and medical industries, where audit trails and regulatory compliance are crucial, benefit greatly from this feature.

Technical Excellence and Customer Support

Our engineering staff offers thorough technical consulting services, helping clients with application-specific advice, design optimization, and material selection. This knowledge aids clients in achieving peak performance while perhaps cutting expenses via material replacements or design enhancements.

Our ability to manufacture fasteners to client designs or specifications allows us to meet certain needs that conventional products are unable to meet. Prior to full-scale manufacturing, our fast prototype services allow comprehensive validation and streamline product development timelines.

Conclusion

US consumers that purchase titanium shoulder bolts from China gain from a mix of cost effectiveness, sophisticated production capabilities, and all-encompassing quality systems that are competitive with local options. Careful supplier selection, extensive qualification procedures, and the establishment of transparent communication channels that guarantee needs are comprehended and regularly fulfilled are the keys to effective procurement. With continuous investments in technology and quality processes that bolster its standing as a dependable supplier of precision fasteners, China's titanium processing sector is still developing. Businesses like Chuanglian show the industry's dedication to fulfilling global quality standards while giving affordable pricing and technical assistance that goes above and beyond the normal product offering.

FAQ

Q1: How do titanium shoulder bolts compare to stainless steel alternatives?

A: Compared to stainless steel, titanium shoulder bolts have better strength-to-weight ratios and weigh around 40% less while retaining similar or better mechanical qualities. Additionally, titanium offers superior corrosion resistance in a variety of settings, especially chemical and marine applications. Stainless steel substitutes, on the other hand, are usually less expensive and can be suitable for less demanding applications where weight reduction is not essential.

Q2: What methods verify the quality of titanium shoulder bolts from Chinese manufacturers?

A: QDimensional inspection reports showing adherence to requirements, surface finish measures, and material test certificates attesting to mechanical and chemical composition are all examples of quality verification. Additional assurance is provided by independent third-party testing, especially for important applications. Verification of certification and supplier audits guarantee that production procedures adhere to the necessary requirements.

Q3: What are typical lead times for bulk orders of titanium shoulder bolts from China?

A: Depending on their complexity, bespoke orders may take up to 4-6 weeks to produce and ship, whilst standard configuration orders usually take 2-4 weeks. Extra time can be needed for unique materials or large volume orders. In order to prevent rush order surcharges and guarantee sufficient inventory availability, procurement plans should be planned around these periods.

Partner with Chuanglian for Your Titanium Shoulder Bolt Requirements

Ready to experience the advantages of working with a leading titanium shoulder bolts manufacturer? Chuanglian offers comprehensive solutions tailored to your specific requirements, backed by over ten years of titanium processing expertise. Our team provides detailed technical consultations, competitive pricing, and rapid sample development to support your procurement decisions. Contact us today at info@cltifastener.com or djy6580@aliyun.com for customized quotes and technical specifications.

References

1. Zhang, L. and Wang, M. "Titanium Fastener Manufacturing in China: Industry Analysis and Quality Standards." International Journal of Advanced Manufacturing Technology, 2023.

2. American Society for Testing and Materials. "Standard Specification for Titanium and Titanium Alloy Fasteners." ASTM F467-23, 2023.

3. Johnson, R.K. "Global Supply Chain Analysis of Titanium Components for Aerospace Applications." Aerospace Materials Quarterly, Vol. 45, No. 3, 2023.

4. Chen, H. et al. "Comparative Analysis of Titanium Processing Capabilities: China vs. Global Markets." Materials Science and Engineering Review, 2023.

5. International Titanium Association. "Market Report on Titanium Fastener Production and Trade Patterns." Annual Industry Survey, 2023.

6. Liu, S. and Thompson, D. "Quality Assurance in Chinese Titanium Manufacturing: Best Practices and Certification Standards." Quality Engineering International, 2023.

Learn about our latest products and discounts through SMS or email