- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Buying Wholesale Titanium Fairing Bolts: Sourcing Tips

Sourcing wholesale titanium fairing bolts requires strategic planning and expertise in material science to ensure optimal procurement decisions. These premium fasteners represent a critical investment in aerospace, marine, and high-performance applications where strength, corrosion resistance, and weight reduction are paramount. Understanding supplier capabilities, certification requirements, and quality standards becomes essential when purchasing titanium fairing bolts in bulk quantities. The procurement process involves evaluating multiple factors including material grades, manufacturing precision, delivery timelines, and long-term partnership potential. This comprehensive guide provides procurement professionals with practical strategies and industry insights to navigate the complex landscape of titanium fastener sourcing effectively.

Understanding Titanium Fairing Bolts: Key Specifications and Advantages

Titanium fairing bolts are the top of the line when it comes to engineered fastener technology. They combine remarkable material qualities with precise manufacture to give unrivaled performance in situations that are very demanding. Titanium alloys, primarily Grade 5 (Ti-6Al-4V), are used in the production of these specialty components. These alloys provide an excellent mix of courage, weight, and corrosion resistance, which puts them in a position that is much superior than typical steel alternatives.

Material Composition and Grades

The meticulous choosing of metal alloys that are in accordance with demanding industry criteria is the cornerstone of exceptional titanium fairing bolts. Titanium alloy grade 5, which is composed of 6% anodized and 4% vanadium, has remarkable tensile strength while retaining the lightweight properties that make titanium a useful material for applications that are sensitive to weight. Although it weighs around forty percent less than high-strength steel, this alloy composition has tensile strength values that are more than one hundred thirty thousand pounds per square inch (PSI).

In situations where the necessity for high corrosion resistance is more important than the requirement for ultimate strength, pure titanium solutions are also available. These versions perform very well in chemical processing applications and maritime settings, both of which need uncompromising substance over lengthy service periods due to the presence of hostile components.

Manufacturing Precision and Standards

In order to fulfill the stringent requirements of aerospace or precision engineering applications, CNC machining technologies provide accurate dimensions and surface quality that is of the highest possible standard. Computer-controlled procedures are used in the production process to ensure that tolerances are maintained within a range of ±0.001 inches. This method guarantees that the thread engagement is constant and that the load distribution is ideal throughout the fastener assembly.

In order to comply with quality standards, it is necessary to conform to the requirements of ASTM B348, Ansi F136, ISO 9001:2008, and AMS 4928. These certifications grant procurement teams the assurance that the items they purchase satisfy worldwide norms for the characteristics of the materials, the correctness of the dimensions, and the dependability of the performance across a variety of operating settings.

Surface Treatment Options and Benefits

The already excellent qualities of titanium shielding bolts are further enhanced by the use of advanced surface treatments, which are accomplished via specialized finishing procedures. The process of anodizing results in the formation of an oxide protective film that enhances the resistance to corrosion. Additionally, it provides the opportunity for aesthetic customization via a variety of color possibilities, such as natural titanium, gold, green, blue, purple, black, even rainbow finishes.

Polishing techniques provide surface finishes that are reflective, therefore reducing the amount of friction that occurs during installation and providing an increased visual appeal for applications that are being exposed. Nitriding techniques enhance surface hardness и wear resistance, which extends service life in frequent use applications that include repetitive assembly and disassembly. It also increases the surface's resistance to wear.

How to Select the Right Titanium Fairing Bolts for Your Procurement Needs

Selecting appropriate titanium fairing bolts requires comprehensive evaluation of application-specific requirements, environmental conditions, and performance expectations. The decision-making process involves analyzing multiple technical parameters while balancing cost considerations against long-term operational benefits and reliability requirements.

Load Capacity and Stress Analysis

Understanding the mechanical loads that titanium fairing bolts must withstand becomes critical when specifying appropriate grades and configurations. Grade 5 titanium alloy provides ultimate tensile strength of approximately 130,000 PSI with yield strength around 120,000 PSI, making it suitable for high-stress applications in aerospace and automotive sectors.

There is a direct correlation between the selection of thread size and the load-carrying capability, with popular combinations consisting of M5, M6, and M8 arrangements. In situations when conventional dimensions are unable to fulfill certain geometric or performance criteria, specialist applications might benefit from the availability of custom size choices. It is important for engineering teams to undertake comprehensive stress analysis in order to guarantee that the chosen fasteners provide sufficient safety margins under the highest loads that are predicted.

Environmental Compatibility Assessment

Titanium is an excellent material for applications that need it to be exposed to sea water, chemicals, and significant temperature fluctuations because of its great resistance to corrosion. Titanium fasteners have a considerable advantage over steel anchors in mixed-material assemblies because of the natural oxide layer that accumulates on titanium surfaces. This layer offers passive shielding against corrosion from galvanic attack when titanium is used with metals that are not comparable to one another.

When subjected to cryogenic circumstances up to 400 degrees Celsius (752 degrees Fahrenheit), Grade 5 titanium maintains its mechanical qualities. Temperature performance stays steady throughout a broad range of temperatures. In applications that include extensive temperature cycling or harsh operating conditions, this thermal stability guarantees that the performance of the fastener will remain constant.

Thread Configuration and Installation Requirements

The configurations of hex head of socket head each provide their own unique set of benefits, which vary according to the access limits and torque needs respectively. It is possible to install socket head cap screws in restricted locations when wrench access is limited. These screws provide superior strength-to-size ratios than other types of screws. As well as giving visual confirmation of the correct position, hex head bolts make installation simpler and more straightforward with common tools.

Calculations of the thread pitch the engagement length guarantee that there is sufficient gripping strength while also avoiding thread stripping during the installation process. The correct torque parameters, which normally range from fifty to seventy percent of the bolt's maximum strength, prevent the bolt from being overtightened while still guaranteeing that the system is secure enough to withstand operating loads.

Sourcing Titanium Fairing Bolts Wholesale: Best Practices and Tips

Wholesale procurement of titanium fairing bolts demands strategic supplier evaluation, rigorous quality verification, and comprehensive supply chain management to ensure consistent delivery of premium products. The sourcing process involves multiple stakeholders and extended evaluation periods that require careful coordination and technical expertise.

Supplier Qualification and Certification Verification

Identifying qualified suppliers requires thorough evaluation of manufacturing capabilities, quality systems, and certification compliance. AS9100 certification indicates aerospace industry compliance, while ISO 9001 demonstrates comprehensive quality management systems. Medical device manufacturers should verify ISO 13485 certification when sourcing bolts for biocompatible applications.

Evaluation of CNC milling equipment, inspection aptitudes, and production volume constraints are all components of the manufacturing capacity assessment. In order to show their capacity, suppliers should demonstrate that they are able to maintain a high standard over big production runs while also maintaining delivery dates that match with project timetables and regulations for inventory management.

Through the use of material certifications, inspection reports, and production records, traceability documentation offers a vital form of quality assurance. In addition to supporting auditing standards and quality system maintenance, these papers make it possible to verify the material composition, mechanical qualities, and dimensional conformity of the product.

Price Negotiation Strategies and Terms

When procurement teams have a better understanding of the intricacies of the titanium market, they are better equipped to negotiate good price while also being aware of the value of bronze material and processing expenses. However, the minimum order size must be in accordance with inventory management expenses and cash flow concerns in order to be considered. Volume commitments often make it possible to get cheaper price via economies of scale.

Payment terms negotiation should balance supplier cash flow requirements with organizational procurement policies. Extended payment terms may increase unit costs, while early payment discounts can provide cost savings that improve overall procurement value.

Long-term supply agreements provide price stability and guaranteed capacity allocation during periods of high market demand. These arrangements often include volume commitments that enable suppliers to invest in dedicated capacity while providing buyers with predictable costs and delivery schedules.

Quality Assurance and Inspection Protocols

Incoming inspection procedures for critical items like titanium fairing bolts verify that received products meet specified requirements through dimensional measurement, material verification, and visual examination. Statistical sampling plans provide confidence in batch quality while maintaining reasonable inspection costs and delivery schedules.

Material testing includes tensile strength verification, hardness measurement, and chemical composition analysis. These tests confirm that material properties meet specification requirements while identifying potential quality issues before products enter production or assembly processes.

Documentation review includes material certifications, inspection evaluations, and compliance declarations that support traceability rules and quality management. These statements are included in the documentation review review. With the right documentation, it is possible to effectively monitor the performance of suppliers and implement programs for continuous improvement.

Installation and Maintenance Guidelines for Titanium Fairing Bolts

In order to avoid over-tightening and the possibility of thread damage, torque standards need to be altered when working with titanium because of its lower stiffness of elasticity in comparison to steel. The values of torque normally fall anywhere between fifty and seventy percent of the ultimate strength that has been determined, with particular values varying according to the threading size, grade, and purpose requirements.

Installation Tools and Techniques

Titanium's lower modulus of elasticity compared to steel requires adjusted torque specifications to prevent over-tightening and potential thread damage. Torque values typically range from 50-70% of calculated ultimate strength, with specific values depending on thread size, grade, and application requirements.

Through the use of proper compounds, thread lubrication may minimize the amount of tension that is required for installation while also avoiding galling across titanium surfaces. The optimum results may be achieved using anti-seize compounds that have been particularly designed for titanium applications. These compounds do not compromise the material compatibility or corrosion-resistant properties of the titanium.

Installation sequence planning prevents access problems and ensures proper fastener engagement across multi-bolt assemblies. Progressive torquing procedures distribute loads evenly while preventing distortion or stress concentration that could compromise assembly integrity.

Maintenance Schedules and Inspection Methods

Regular inspection intervals depend on application severity and environmental exposure conditions. Visual examination identifies signs of wear, corrosion, or mechanical damage that might compromise fastener performance or safety margins.

Through the use of mild processes that protect surface coatings and dimensional correctness, cleaning operations ensure that corrosion-resistant properties and aesthetic appeal are maintained. In order to remove pollutants without causing any damage to anodized coatings or polished surfaces, gentle detergents when soft brushes are used.

Through the use of torque verification during care cycles, it is possible to discover potential thread wear or loosening concerns while also ensuring that adequate preload is maintained. The documentation of inspection findings provides assistance for maintenance forecasting programs and assists in optimizing service intervals based on data pertaining to actual performance.

Replacement Criteria and Lifecycle Management

Titanium fairing bolts often have improved corrosion resistance + fatigue performance compared to steel counterparts, which accounts for the reason why their service life expectancies are typically higher. Nevertheless, replacement is required when a visual assessment indicates considerable wear, rust, or mechanical degradation that might affect the safety or function of the item.

Inventory management strategies balance carrying costs against availability requirements, considering lead times for specialty configurations and custom specifications. Standardization initiatives reduce inventory complexity while maintaining adequate coverage for critical applications.

The cost-benefit analysis comparing replacement costs against potential failure consequences should include critical components such as titanium fairing bolts. This helps establish appropriate replacement intervals and inventory levels. The analysis must consider both direct costs and potential operational disruptions or safety implications.

Company Introduction and Our Offerings

Baoji Chuanglian New Metal Material Co., Ltd. stands as a premier manufacturer and exporter of titanium products, strategically located in Baoji City, renowned globally as the "City of Titanium." Our company represents a technological and innovative enterprise specializing in research, production, and precision machining of various titanium and rare metal products that serve the most demanding industrial applications.

Manufacturing Expertise and Production Capabilities

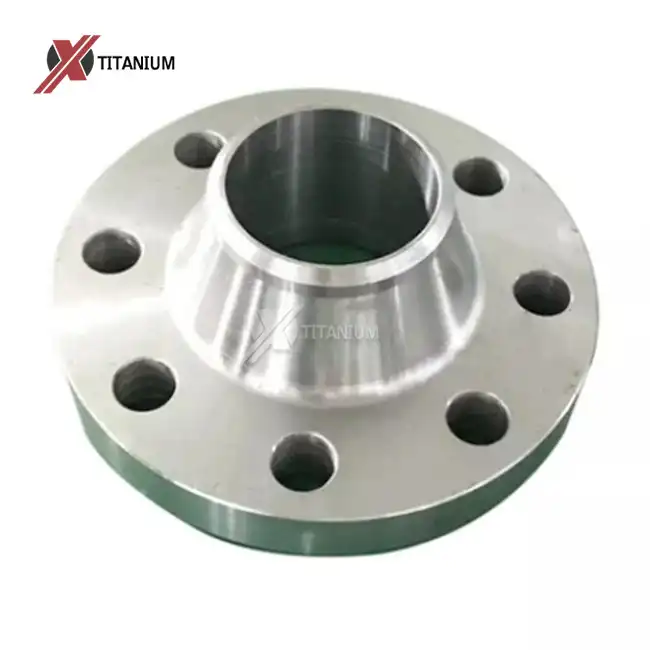

Our extensive experience spanning more than ten years in titanium product machining and research positions us as industry leaders in delivering superior quality fasteners and components. The comprehensive business scope encompasses titanium fasteners, rods, wire, plates, tubes, flanges, and various machined titanium components alongside refractory metal products that meet the stringent requirements of aerospace, petrochemical, medical, and marine applications.

Advanced manufacturing infrastructure includes more than a dozen CNC machine tools and sophisticated mechanical processing equipment that ensure precision manufacturing and consistent quality. Through continuous accumulation and development, our company maintains a quality-foremost operational approach while emphasizing synchronous technology and equipment updates that keep pace with evolving industry demands.

Technical expertise encompasses strict adherence to national, international, and industry standards while maintaining focus on training and developing exceptional technicians. This commitment to excellence ensures that our manufacturing processes remain comprehensive while production capacity meets diverse machining demands across multiple industry sectors.

Quality Control Systems and Certifications

Rigorous quality control systems monitor every production stage from raw material selection through finished product delivery, ensuring that customers receive consistently high-quality products that meet or exceed specifications. Each production link undergoes strict inspection protocols that verify material properties, dimensional accuracy, and performance characteristics.

International recognition comes through successful supply relationships with numerous well-known companies worldwide, where our quality titanium products have undergone extensive field testing over many years. This proven track record, combined with excellent customer service, consistent quality, and reliable delivery performance, has earned recognition and trust from valued customers across diverse industries.

Certification compliance includes adherence to ISO quality standards, ASTM material specifications, and industry-specific requirements that support customer quality systems and regulatory compliance needs. Our commitment to maintaining these standards ensures reliable supply chain partnership for critical applications where quality and reliability cannot be compromised.

Conclusion

Successful procurement of wholesale titanium fairing bolts requires comprehensive understanding of material properties, supplier capabilities, and application requirements that influence long-term performance and cost-effectiveness. The strategic approach involves balancing technical specifications against budget constraints while establishing reliable supply chain partnerships that support operational excellence. Quality assurance through proper supplier qualification, rigorous inspection protocols, and comprehensive documentation provides confidence in product performance across demanding applications. Investment in titanium fairing bolts delivers superior value through enhanced durability, weight reduction, and corrosion resistance that exceeds traditional fastener alternatives while supporting sustainability initiatives through extended service life.

Partner with Chuanglian for Premium Titanium Fairing Bolts

Chuanglian delivers exceptional value through comprehensive titanium fairing bolt solutions that meet the most demanding industrial requirements. Our extensive manufacturing expertise, advanced CNC machining capabilities, and rigorous quality control systems ensure consistent delivery of premium products that exceed customer expectations. Whether you need standard configurations or custom specifications, our technical consultation services help identify optimal solutions while our responsive customer support team provides dedicated assistance throughout the procurement process.

Connect with our experienced team at info@cltifastener.com or djy6580@aliyun.com to discuss your specific requirements and receive detailed quotations tailored to your application needs. As a trusted titanium fairing bolts manufacturer, we offer competitive wholesale pricing, flexible shipping arrangements, and comprehensive technical support that streamlines your sourcing process.

References

1. ASM International Handbook Committee. "Properties and Selection: Nonferrous Alloys and Special-Purpose Materials." ASM International Materials Handbook, Volume 2, 2018.

2. Boyer, R.R., Welsch, G., and Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International, 2019.

3. Donachie, Matthew J. "Titanium: A Technical Guide, Second Edition." ASM International Technical Publications, 2020.

4. Lutjering, Gerd and Williams, James C. "Titanium Engineering Materials and Processes." Springer-Verlag Engineering Materials Science, 2021.

5. Peters, M., Kumpfert, J., Ward, C.H., and Leyens, C. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials Industrial Applications Review, 2019.

6. Rack, H.J. and Qazi, J.I. "Titanium Alloys for Biomedical Applications." Materials Science and Engineering Research Annual, 2020.

Learn about our latest products and discounts through SMS or email