- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Choose a Reliable Titanium Fastener Supplier

When choosing a trustworthy source of titanium fasteners, you need to think about their technical knowledge, quality certifications, and experience making things. Experts in procurement must evaluate suppliers of titanium micro screws and other precision fasteners based on their ability to follow the rules, maintain consistent quality, and provide full technical assistance. When making a selection, price is just one factor to think about. Others include manufacturing capacity, material traceability, and the possibility of working together for a long time on difficult projects in the aerospace, medical device, and high-performance engineering fields.

Comprehending Your Titanium Fastener Requirements

Identifying Application-Specific Needs

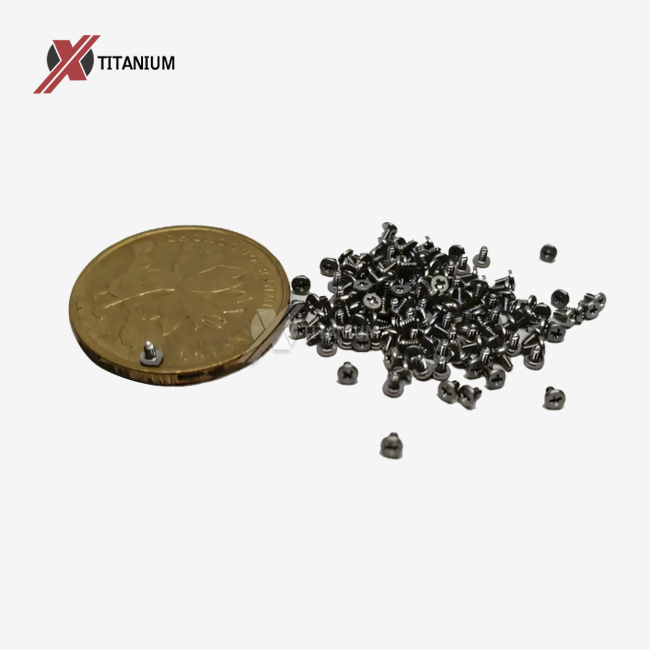

Modern industrial uses need titanium fasteners that are made with accuracy and fulfill strict performance specifications. For surgical implants, medical device makers require biocompatible titanium micro screws. The purity of the material and the polish on the surface both have a direct effect on patient safety. Aerospace engineers use grade 5 titanium alloys (Ti-6Al-4V) for structural parts that need to be light and strong enough to handle high temperatures and mechanical stress.

Understanding the exact grade requirements for your application is an important step in choosing the right material. Titanium alloys are preferable for high-stress situations because they have greater mechanical qualities. Pure titanium is great for maritime conditions since it doesn't rust. Custom sizes from M1 to M3 meet a variety of assembly needs, and certain applications may need specialized thread combinations.

Volume and Customization Considerations

When buying things for business, you frequently have to strike a balance between having the right products and needing to make them unique. Small-batch production runs need suppliers that can adapt to different manufacturing needs, while big projects need to make sure that the quality stays the same throughout extended delivery times. Anodizing, polishing, and nitriding are all ways to change the surface of an object that may make it seem better and work better. There are also bright anodized finishes in gold, blue, green, purple, black, and rainbow colors, in addition to natural titanium finishes.

Establishing Core Criteria for Supplier Selection

Quality Standards and Certifications

High-end providers of titanium fasteners have extensive quality control systems that are in line with industry norms. Compliance with ASTM B348 and ISO 5832 guarantees material uniformity and manufacturing batch performance dependability. While AS9100 certification shows aerospace sector expertise, medical-grade certifications verify biocompatibility for healthcare applications.

Reputable providers are distinguished from rivals in the titanium fastener industry by the following quality indicators:

• Systems for material traceability that record the origins of raw materials and their processing histories throughout the production chain

• Advanced testing capabilities, such as dimensional inspection processes, chemical composition analysis, and mechanical property verification

• Processing in a controlled environment to avoid contamination during surface treatment and CNC machining

• The use of statistical process control that keeps an eye on production factors and guarantees constant output quality

These quality management procedures are crucial assessment factors for purchasing choices as they have a direct effect on product performance and regulatory compliance.

Manufacturing Capabilities Assessment

One essential need for producing accurate titanium fasteners is proficiency in CNC machining. The special qualities of titanium, such as its poor heat conductivity and propensity for work hardening, must be handled expertly by suppliers. Cutting settings and sophisticated manufacturing techniques maximize surface smoothness while preserving the precise dimensional tolerances necessary for crucial applications.

Evaluation of production capacity takes into account both present capabilities and future scalability. Suppliers can accept different order quantities while keeping delivery dates on track if they have a number of CNC machine tools and related processing equipment. A supplier's dedication to competitive performance and ongoing development is shown by their investment in contemporary production technologies.

Comparing Titanium Micro Screws Suppliers

Technical Expertise and Innovation

Prominent providers of titanium fasteners set themselves apart with their application knowledge and technological innovation. Superior product solutions and technical support services are often offered by businesses with strong R&D departments. Their technical teams work with clients to improve titanium micro screws and other fastener designs for particular uses, taking into account elements like material choice, head configurations, and thread engagement.

A supplier's comprehension of the market and production adaptability are shown in the variety of products they provide. The capacity to efficiently service diverse sectors is shown by extensive fastener portfolios that comprise a variety of head types, thread patterns, and customized combinations. For complicated projects, suppliers with both standard items and unique production skills give more procurement choice.

Customer Service and Support Infrastructure

Order management, technical advising, and post-purchase assistance are all included in professional customer service. Dedicated account management guarantees constant contact throughout the procurement process, and skilled application engineers help with material selection and specification development. Multilingual assistance skills lower communication barriers and promote worldwide business collaborations.

For sectors that are subject to regulations, documentation and reporting services are quite valuable. Quality verification procedures are streamlined by suppliers that provide comprehensive material certifications, test reports, and compliance documents. Electronic data management solutions improve overall procurement efficiency by facilitating effective information exchange and project monitoring.

Validation and Engagement Strategies

Sample Testing and Verification Protocols

Analyzing samples gives important information about the capabilities of suppliers and the quality of their products. Thorough testing procedures should evaluate mechanical characteristics pertinent to the intended use, surface finish quality, and dimensional correctness. Spectroscopic investigation of the material composition verifies grade standards and detects any impurities.

Performance qualities under simulated operating settings are validated using physical testing processes. Corrosion resistance testing verifies environmental endurance, whereas torque testing assesses thread engagement and retention qualities. These validation procedures guarantee product appropriateness for demanding applications and lower procurement risks.

Supply Chain Reliability Assessment

A supplier's operational dependability and logistical skills may be inferred from their delivery performance history. Efficient production planning and inventory management systems are shown by consistent on-time delivery records. Proficiency in international shipping becomes essential for worldwide procurement activities, necessitating understanding of regulatory compliance, paperwork needs, and customs processes.

Potential supply chain interruptions and quality problems should be addressed by risk mitigation techniques. More supply security is offered by suppliers that have strong backup plans and quality control procedures. Clear return and warranty guidelines guard against faulty goods and guarantee prompt problem solving.

About Chuanglian Titanium Fastener Solutions

Baoji Chuanglian New Metal Material Co., Ltd. has been making precision titanium fasteners for more than 10 years. Our plant is located Baoji City, which is renowned as the "City of Titanium." It has state-of-the-art CNC machining and strict quality control systems that let us make great titanium micro screws and custom fastener solutions.

We have expertise making things out of titanium alloys and pure titanium, with a concentration on Grade 5 (Ti-6Al-4V) applications. Advanced surface treatment options including polishing, anodizing, and nitriding make it possible to fully customize your product. The product may be used in chemical processing, aerospace, medical devices, marine engineering, and other high-performance industrial fields where precision and reliability are very important.

Quality assurance methods make sure that products work the same way all the time, from checking the raw materials to delivering them. Our strict quality control system keeps an eye on every stage of the production process to make sure that we meet both national and international standards. CNC machining can handle both small and big orders, allowing for customized needs while yet keeping production schedules on track. Technical support services assist customers choose out materials, write specs, and make the most use of their apps.

Conclusion

When picking a reliable titanium fastener supplier, you need to carefully look at their technical skills, quality methods, and customer service systems. When looking for long-term connections, the assessment method has to look at things like production capability, material knowledge, and following the rules. Suppliers of high-quality titanium micro screws and precise fasteners need to have advanced CNC machining skills, dependable testing methods, and thorough record-keeping systems. By checking suppliers' capabilities and testing samples, you may minimize the risks of buying things and make sure that the products work well in important situations.

FAQ

Q1: What advantages do titanium micro screws offer over stainless steel alternatives?

A: Titanium micro screws are perfect for medical and aeronautical applications because of their outstanding strength-to-weight ratios, remarkable corrosion resistance, and biocompatibility qualities. In some settings, their chemical inertness and non-magnetic characteristics provide further benefits.

Q2: How do I select the appropriate size and thread configuration?

A: Material thickness, assembly limitations, and load requirements all influence size choices. Metric threads (M1-M3) are often used for precision applications, while thread configurations vary depending on the requirements of the application. Optimizing fastener specifications is aided by technical contact with knowledgeable suppliers.

Q3: Can suppliers accommodate both custom manufacturing and bulk procurement needs?

A: Prominent producers of titanium fasteners provide a range of manufacturing options, from scale production to prototype development. While maintaining uniform quality standards, custom specifications, surface treatments, and packaging choices satisfy a range of procurement needs.

Partner with Chuanglian for Premium Titanium Micro Screws

Chuanglian provides outstanding titanium fastener solutions supported by cutting-edge production capability and thorough quality control. For demanding applications in a variety of sectors, our skilled staff offers dependable delivery, customized specifications, and technical assistance. As a reputable producer of titanium micro screws, we guarantee exceptional product performance by combining meticulous quality control with precise CNC machining. Contact our technical specialists at info@cltifastener.com or djy6580@aliyun.com to discuss your specific requirements and receive detailed quotations.

References

1. American Society for Testing and Materials. "Standard Specification for Titanium and Titanium Alloy Bars and Billets." ASTM International, 2019.

2. International Organization for Standardization. "Implants for Surgery - Metallic Materials - Part 3: Wrought Titanium 6-Aluminium 4-Vanadium Alloy." ISO 5832-3, 2016.

3. Boyer, R.R. "An Overview on the Use of Titanium in the Aerospace Industry." Materials Science and Engineering A, vol. 213, 2018.

4. Rack, H.J. and Qazi, J.I. "Titanium Alloys for Biomedical Applications." Materials Science and Engineering C, vol. 26, 2017.

5. Lutjering, G. and Williams, J.C. "Titanium: Engineering Materials and Processes." Springer-Verlag Berlin Heidelberg, 2020.

6. Donachie, Matthew J. "Titanium: A Technical Guide, Second Edition." ASM International Materials Park, 2019.

Learn about our latest products and discounts through SMS or email

_1751274537597.webp)