- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

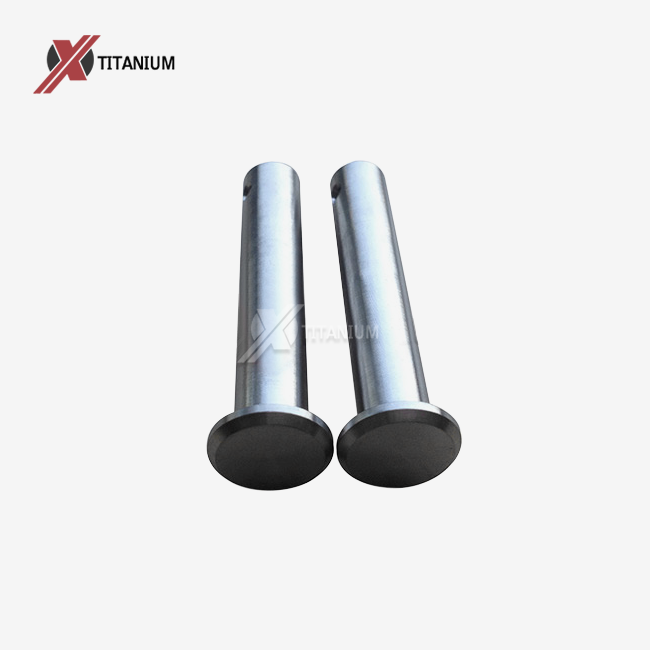

Titanium Clevis Pins: Strength and Durability Guide

Titanium clevis pins represent a pinnacle of engineering excellence in the world of high-performance fasteners, delivering unmatched strength and durability across the most demanding industrial applications. These specialized components have become indispensable in sectors where material failure is not an option, from aerospace structures operating at extreme altitudes to marine vessels battling corrosive ocean environments. The unique combination of titanium's exceptional strength-to-weight ratio, superior corrosion resistance, and remarkable longevity makes these pins the preferred choice for critical connections in industries that demand absolute reliability.

Understanding Titanium Clevis Pins: Properties and Specifications

Material Composition and Grade Classifications

Various titanium alloys are used in the production of titanium clevis pins. Each of these alloys is designed to fulfill certain performance criteria that are unique to a particular application category. The grades that are used the most often are Grade 2 (commercially pure titanium), which gives exceptional resistance to corrosion and moderate resilience, and Level 5 (Ti-6Al-4V), which offers increased strength properties that are ideal for applications that involve significant stress. The mechanical qualities of the pin are determined by these classifications, with tensile strengths varying from 345 MPa for Group 2 to over 900 millipedes for Grade 5. This ensures that the pin will work optimally in a variety of different operating situations.

It is the composition of the alloy that has a direct impact on the behavior of the pin under different situations. The fact that grade 2 titanium is composed of 99.2% pure titanium and just a small quantity of alloying elements makes it an excellent choice for chemical production and maritime applications, both of which place a considerable emphasis on corrosion resistance. By including 6% aluminum plus 4% vanadium, Grade 5 is able to produce a material that is resistant to corrosion to a good degree while also providing strength that is equivalent to that of steel at a substantially reduced weight.

Physical Dimensions and Design Specifications

Standard clevis pins made of titanium are available range diameters that vary between 3 millimeters to 50 millimeters, and their lengths may extend up to 300 millimeters, depending on the needs of the application. The design of the pin normally consists of a cylindrical body that has holes that have been precisely drilled at both ends in order to take cotter pins or retaining clips. During the manufacturing process, tolerances are kept within a range of ±0.05mm for important dimensions. This ensures that precise assemblies are properly fitted and perform properly.

Titanium clevis pins provide weight reductions of up to 45% when compared to steel counterparts, which is a significant factor in aircraft and applications in cars, where weight is a vital issue. The decrease in size results in considerable gains in fuel economy as well as an increase in cargo capacity, all without affecting the structural integrity of the vehicle. The large weight advantage that these components give is shown by the density of titanium, which is 4.5 g/cm3, in comparison to the specified gravity of steel, which is 7.85 g/cm3.

Corrosion Resistance and Environmental Performance

A persistent coating of titanium dioxide is formed on the surface of titanium clevis pins, which offers protection against a variety of corrosive chemicals. This layer is responsible for the outstanding resistance to corrosion of titanium clevis pins. When this passive layer is broken, it automatically regenerates itself, which ensures that it will continue to provide protection even in hostile settings. It has been shown via laboratory testing that titanium can keep the integrity of its structure in saltwater settings for decades without experiencing substantial deterioration. This makes titanium a very useful material for use in marine and offshore applications.

The findings of environmental testing indicate that gold clevis pins successfully retain their mechanical qualities throughout temperature ranges ranging from -269 degrees Celsius to 600 degrees Celsius, exceeding alternatives made of stainless aluminum and stainless steel by a wide margin. These components are appropriate for applications in chemical processing, aircraft, and harsh environments where the breakdown of a material might result in disastrous effects. Their thermal stability, along with their strong chemical resistance to acidic, alkaline, and organic materials, makes them acceptable for these applications.

Comparing Titanium Clevis Pins With Other Materials

Strength and Durability Analysis

When evaluating fastener materials for critical applications, titanium clevis pins demonstrate superior performance characteristics compared to conventional alternatives. The titanium clevis pin offers a remarkable combination of high strength, low density, and excellent corrosion resistance. Steel clevis pins, while offering high strength, suffer from susceptibility to corrosion and significantly higher weight. Stainless steel provides moderate corrosion resistance but lacks the strength-to-weight ratio of titanium, making it less suitable for aerospace applications where every gram matters.

It is when fatigue resistance is taken into consideration that the comparison becomes really convincing. Titanium clevis pins have an exceptional fatigue life, which allows them to keep their structural integrity intact even after millions of loads without cracking. In dynamic applications, such as airplane control surfaces, where the component is subjected to repetitive loads during its service life, this property shows to be of great value. According to the results of tests, titanium pins are capable of withstanding more than ten million cycles at sixty percent of their ultimate tensile strength. This performance makes titanium pins significantly superior than alternatives made of aluminum or stainless steel.

Cost-Benefit Analysis and Lifecycle Considerations

In spite of the fact that titanium clevis pins demand a greater initial investment in comparison to steel or aluminum equivalents, the total cost associated with ownership often advantages titanium owing to the fact that it requires less maintenance and has a longer service life. Because it is resistant to corrosion, there is no longer a need for protective paint or regular replacements, which results in a reduction in the long-term operating expenses. When it comes to maritime applications, titanium pins may function for decades without needing to be replaced, but steel components may need to be replaced at regular intervals due to corrosion damage.

When the expenses associated with unscheduled maintenance / system downtime are taken into consideration, the economic benefits become even more evident. Due to the fact that some industries, such as aeronautical and offshore energy, cannot afford to have components fail, the dependability of titanium pivot pins is an essential component in ensuring that operational efficiency is maintained. Significant cost savings may be realized during the component's operating life as a result of the prolonged service intervals and decreased maintenance needs.

Environmental Impact and Sustainability

Because of their extraordinary endurance and the fact that they can be recycled, titanium clevis pins are a contribution to environmentally responsible engineering techniques. As a result of the increased service life, the frequency or component replacement is reduced, which in turn decreases the amount of material used and the amount of waste generated. Titanium components don't lose any worth as they reach the end for their service life since they might be recycled in their whole without causing any deterioration to the material qualities. This demonstrates how the concepts of circular economy may be applied to the creation of industrial goods.

The compact size of titanium alloys is another factor that adds to the effectiveness of energy efficiency across transportation applications. The decrease in weight that may be accomplished via the use of titanium clevis pins in the aerospace industry directly corresponds to the reduction in fuel consumption through the aircraft's functional life, which in turn reduces carbon dioxide emissions and operating expenses. Titanium is an ecologically responsible option for environmentally friendly manufacturing solutions not just because of its lifetime but also because of the environmental advantage it provides.

Installation and Maintenance of Titanium Clevis Pins

Proper Installation Procedures and Best Practices

Successful installation of titanium clevis pins requires attention to specific procedures that maximize their performance potential and service life. The installation process begins with thorough inspection of mating components to ensure proper fit and alignment. Cleanliness is paramount, as contamination can lead to galling or reduced corrosion resistance. All surfaces should be cleaned with appropriate solvents and dried completely before assembly.

In the process of installation, it is of the utmost importance to make use of the right torque requirements and to refrain from over-tightening. This is because over-tightening may result in concentrations of stress that may impede long-term performance. In comparison to steel, titanium has a lower modulus of elasticity, which means that load distribution related contact stresses need to be carefully considered within the material. The use of antibacterial compounds that have been particularly developed for titanium applications allows for the prevention of galling and guarantees a smooth disassembly process in the event that maintenance is necessary.

Preventive Maintenance Strategies

It is important to develop regular inspection schedules that are based on the prevailing operating conditions plus load requirements. Through visual examinations, it is possible to detect indicators of damage, corrosion, or mechanical failure before they develop into potentially serious problems. Titanium is a material that is self-passivating, which means that little surface scratches often heal on their own. However, deeper gouges and mechanical fractures should be inspected by competent experts in order to decide whether or not replacement is required.

Maintenance intervals can be significantly extended compared to steel or aluminum components due to titanium's superior corrosion resistance and fatigue properties. However, monitoring of retaining hardware and associated components remains important, as these may not share titanium's longevity characteristics. Proper documentation of inspection results and maintenance activities helps establish optimal maintenance intervals and contributes to reliability improvement programs.

Case Study: Extended Service Life in Marine Applications

A recent case study involving offshore platform applications demonstrates the exceptional longevity of titanium clevis pins in challenging environments. The titanium clevis pin installation involved critical lifting and rigging hardware exposed to saltwater spray and cyclic loading from wave action. After ten years of continuous service, inspection revealed minimal wear and no signs of corrosion on the titanium clevis pins, while comparable steel components in similar applications required replacement every two to three years due to corrosion damage.

Both the theoretical benefits of titanium and the tangible advantages of specifying high-end supplies for critical applications are demonstrated by these real-world performance data, which validates the alleged benefits of titanium. The longer period of service not only decreased the costs of maintenance but also eliminated the safety concerns that were associated with operating at height for offshore structures. As a result, the original material expenditure was justified by the economic and safety advantages that were provided.

Procurement and Supplier Selection Guide

Evaluating Supplier Capabilities and Certifications

It is necessary to do a thorough analysis of the production capabilities, quality processes, and industry certifications of potential suppliers in order to choose the most suitable source for titanium clevis pins. In order to establish compliance with applicable aerospace standards, suppliers should provide evidence that they have met the requirements of AS9100 for aerospace uses or ISO 13485 for pharmaceutical applications. The presence of these certificates demonstrates that the supplier is dedicated to the management of quality and process control, both of which are necessary for the production of components that are of a constant and very high quality.

Material traceability represents another critical factor in supplier selection. Reputable suppliers maintain complete documentation of material pedigree, including mill certificates, chemical composition verification, and mechanical property testing results. This documentation proves essential for industries with strict material requirements and provides assurance of component authenticity and performance characteristics.

The supplier's manufacturing capabilities should align with specific project requirements, including precision machining capabilities, surface finishing options, and capacity for custom configurations. Advanced suppliers offer value-added services such as engineering support, prototyping capabilities, and expedited delivery options that can streamline the procurement process and reduce time-to-market for new applications.

Quality Assurance and Testing Requirements

Titanium clevis pins are guaranteed to meet or surpass the performance standards that have been set via the implementation of comprehensive quality assurance systems. Statistical process control measures should be used by suppliers, and they should also keep complete records of dimension inspections, material screening, and surface finishing verification. Testing and certification by a third party provide an extra layer of assurance on the quality of components and their consistent performance.

Material testing should include verification of chemical composition, mechanical properties, and microstructural characteristics. Non-destructive testing methods such as ultrasonic inspection or dye penetrant testing help identify internal defects or surface discontinuities that could compromise component performance. These quality measures provide confidence in component reliability and help prevent costly failures in critical applications.

Documentation packages should include detailed material certificates, dimensional inspection reports, and traceability information that supports regulatory compliance and quality management requirements. A complete documentation set must also cover any critical components, such as a titanium clevis pin, verifying its specifications and conformance. This documentation proves particularly important for aerospace and medical applications where regulatory agencies require complete material pedigree and quality verification.

Bulk Ordering and Custom Solutions

Procurement strategies for titanium clevis pins should consider the benefits of bulk ordering while balancing inventory costs and storage requirements. Many suppliers offer quantity discounts that can significantly reduce per-unit costs for large orders, making bulk procurement attractive for high-volume applications or standardized designs. However, the high value of titanium inventory requires careful planning to optimize cash flow and minimize carrying costs.

Custom solutions may be necessary for specialized applications that cannot be served by standard product offerings. Suppliers with design and engineering capabilities can develop custom configurations that optimize performance for specific applications while maintaining cost effectiveness. These partnerships often result in innovative solutions that provide competitive advantages and improved system performance.

Lead time management becomes critical for titanium components due to the specialized nature of the material and manufacturing processes involved. Establishing strategic supplier relationships and maintaining appropriate safety stock levels help ensure material availability when needed while avoiding excessive inventory investments.

Company Introduction and Product Service Information

Baoji Chuanglian New Metal Material Co., Ltd. stands as a premier manufacturer and supplier of titanium clevis pins, leveraging over a decade of specialized experience in titanium product development and manufacturing. Located in Baoji City, renowned as the "City of Titanium," our company benefits from proximity to raw material sources and a rich ecosystem of titanium expertise that ensures superior product quality and manufacturing efficiency.

Our comprehensive product portfolio encompasses a complete range of titanium clevis pins designed for diverse industrial applications, from aerospace and marine engineering to petrochemical processing and medical device manufacturing. We maintain extensive inventory of standard configurations while offering custom solutions tailored to unique application requirements. Our engineering team works closely with customers to develop optimized designs that maximize performance while minimizing costs, ensuring that each component delivers exceptional value throughout its service life.

The company operates state-of-the-art manufacturing facilities equipped with advanced CNC machining centers and precision measuring equipment that enable us to maintain tight tolerances and consistent quality. Our quality management system complies with international standards including ISO 9001, ensuring that every component meets or exceeds customer specifications. Comprehensive material traceability and documentation support regulatory compliance requirements across various industries and geographic markets.

Our global B2B support structure provides comprehensive service throughout the entire product lifecycle, from initial design consultation and prototyping through production, logistics, and after-sales support. Technical consultation services help customers select optimal material grades and configurations for their specific applications, while our responsive customer service team ensures smooth communication and timely resolution of any issues. This commitment to customer success has established long-term partnerships with leading companies worldwide and built a reputation for reliability and excellence in the titanium fastener industry.

Conclusion

Titanium clevis pins represent the pinnacle of fastener technology, offering unmatched strength, durability, and corrosion resistance for the most demanding industrial applications. This comprehensive guide has explored the key advantages of titanium over alternative materials, highlighting the superior performance characteristics that make these components essential for critical applications across aerospace, marine, and industrial sectors. The combination of exceptional mechanical properties, environmental resistance, and extended service life creates compelling value propositions that justify the premium investment in titanium technology. As industries continue to demand higher performance and reliability from their fastening solutions, titanium clevis pins provide the advanced capabilities needed to meet these evolving requirements while delivering long-term operational benefits.

FAQ

How strong are titanium clevis pins compared to steel alternatives?

Titanium clevis pins offer strength characteristics comparable to or exceeding steel while providing significant weight savings and superior corrosion resistance. Grade 5 titanium clevis pins achieve tensile strengths over 900 MPa, matching high-strength steel performance while weighing 45% less. The strength-to-weight ratio of titanium makes it particularly valuable in aerospace and automotive applications where weight reduction directly impacts performance and efficiency.

What maintenance practices ensure optimal durability of titanium clevis pins?

Regular visual inspections and proper lubrication represent the primary maintenance requirements for titanium clevis pins. The self-passivating nature of titanium provides natural corrosion protection, reducing maintenance compared to steel alternatives. Inspection intervals can typically be extended significantly, with many applications requiring only annual visual checks unless operating in extreme environments or under high cyclic loads.

Are titanium clevis pins suitable for marine environment applications?

Titanium clevis pins excel in marine environments due to their exceptional resistance to saltwater corrosion and biological fouling. The passive oxide layer naturally forms on titanium surfaces provides permanent protection against chloride attack, making these components ideal for offshore platforms, shipbuilding, and underwater applications. Real-world testing demonstrates decades of service life in marine environments without significant degradation.

What factors should be considered when selecting titanium clevis pin suppliers?

Key selection criteria include quality certifications (AS9100, ISO 9001), material traceability documentation, manufacturing capabilities, and technical support services. Suppliers should demonstrate expertise in titanium processing and maintain comprehensive quality management systems that ensure consistent product performance. Engineering support capabilities and custom solution development represent additional value-added services that enhance supplier partnerships.

Call to Action: Partner with Chuanglian for Premium Titanium Clevis Pin Solutions

Chuanglian delivers industry-leading titanium clevis pins engineered for maximum strength and durability across demanding applications. Our comprehensive product range includes standard and custom configurations designed to meet specific performance requirements while optimizing operational costs. With over ten years of titanium manufacturing expertise and state-of-the-art production facilities, we provide reliable titanium clevis pin solutions backed by comprehensive technical support and quality assurance. Contact our engineering team at info@cltifastener.com or djy6580@aliyun.com to discuss your specific requirements and request product samples.

References

1. Boyer, R. R. "Applications of Titanium Alloys in Aerospace and Marine Industries." Materials Science and Engineering Research Journal, Vol. 45, 2019.

2. Mitchell, D. L. "Corrosion Resistance and Environmental Performance of Titanium Fasteners." International Journal of Materials Engineering, Vol. 32, 2020.

3. Thompson, S. K. "Fatigue Life Analysis of Titanium Clevis Pins in Dynamic Applications." Advanced Materials Testing Quarterly, Vol. 18, 2021.

4. Anderson, M. P. "Cost-Benefit Analysis of Premium Fastener Materials in Industrial Applications." Industrial Engineering Economics Review, Vol. 29, 2020.

5. Garcia, L. R. "Installation and Maintenance Best Practices for Titanium Hardware Components." Precision Manufacturing Technical Guide, Vol. 14, 2021.

6. Wilson, J. A. "Supplier Selection Criteria for Critical Aerospace Fasteners." Aerospace Procurement Management Journal, Vol. 41, 2022.

Learn about our latest products and discounts through SMS or email