Titanium fasteners are much better at preventing corrosion than steel ones because they create a very strong protective oxide layer in less than a second after coming into contact with oxygen. This natural barrier makes titanium micro screws virtually fully rust-proof, thus they last far longer than conventional screws. Titanium is particularly resistant to corrosion because of its remarkable metallurgical properties. These qualities make a protective covering that fixes itself when it becomes broken, so it functions well in even the toughest industrial conditions.

Understanding Corrosion Resistance in Titanium Materials

The best thing about titanium fasteners is that they don't rust. When titanium comes into contact with oxygen, it immediately forms a thick layer of titanium dioxide (TiO₂) that is 2 to 5 nanometers thick. This protective barrier stays strong between -269°C and 600°C, so it's great for situations that are extremely hot or very cold.

The Materials Science Institute completed research that indicates that titanium alloys stay in shape even after being in salt water for 25 years. Steel fasteners, on the other hand, tend to break down a lot after being under the same conditions for 6 to 12 months. Grade 5 titanium (Ti-6Al-4V) corrode at a rate of less than 0.0025mm per year under marine circumstances, whereas stainless steel erode at a rate of 0.127mm per year.

Three main things make titanium more resistant to corrosion:

- Formation of a passive oxide layer that fixes itself in a matter of nanoseconds

- Noble metals that don't corrode when they come into contact with other metals

- Chemical inertness that prevents it from reacting with most acids and bases

Titanium micro screws are better for chemical processing equipment or maritime applications because they are very resistant to stress corrosion cracking caused by chloride.

Comparative Analysis: Titanium vs Steel Fastener Longevity

Laboratory research shows that titanium and steel fasteners work quite differently in a number of settings. Accelerated corrosion testing using ASTM G48 criteria demonstrates that titanium alloys maintain 99.8% of their original strength after 1000 hours of exposure to a 6% ferric chloride solution. In the same circumstances, 316L stainless steel loses around 15-20% of its tensile strength.

The comparison of lifespans shows big differences:

- Marine environments: Titanium fasteners last 50+ years vs 5-10 years for stainless steel

- Chemical processing: Titanium maintains integrity for 30+ years vs 2-5 years for steel

- High-temperature applications: Titanium performs for 25+ years vs 8-12 years for steel

When tested for fatigue at 10⁷ cycles, titanium micro screws maintain 85% of their initial strength, whereas steel fasteners lose 65% of their strength under the same circumstances. Because it is more resistant to fatigue, it needs less maintenance and costs less to own overall. If you require fasteners for aerospace uses where weight and endurance are very important, titanium solutions are better than steel ones since they are 40% lighter and last longer.

The Science Behind Titanium's Rust Immunity

The fact that titanium doesn't rust is due to its special electrochemical characteristics and crystalline structure. When iron-based alloys come into contact with moisture and oxygen, they develop porous iron oxide (rust). In contrast, titanium forms a solid, adherent oxide coating that functions as an impenetrable barrier.

These are the steps that make up the forming process:

- When exposed to air, instant oxidation forms a TiO₂ layer

- Self-healing abilities fix oxide coatings that are broken on their own

- Chemical inertness prevents oxidation from happening deeper than the surface layer

Electrochemical study shows that titanium is noble on the galvanic scale, which means it is comparable to platinum. This makes it very resistant to galvanic corrosion when it is combined with other metals. The usual electrode potential of titanium is -1.63V, which is better than iron's -0.44V. This is why titanium stays stable whereas iron rusts quickly.

Tests that cycle temperatures between -40°C and 150°C show that titanium fasteners keep their protective oxide coating intact. In contrast, steel fasteners develop micro-cracks due to thermal expansion and contraction, which speeds up the process of corrosion.

If you need components that maintain dimensional stability and surface integrity across temperature extremes, then titanium micro screws are more suitable due to their thermal stability and self-healing oxide characteristics.

Cost-Benefit Analysis: Initial Investment vs Long-Term Value

The economic study of titanium fasteners shows that they have a lot of long-term value, even if they cost more up front. Titanium micro screws usually cost 3 to 5 times more than stainless steel screws at first, but their longer lifespan and fewer maintenance needs frequently mean that they cost less over their whole life cycle.

When looking at costs over 20 years of operation, we see:

- Replacement frequency: Steel fasteners require 4-6 replacements vs zero for titanium

- Maintenance downtime: Steel systems average 120 hours vs 15 hours for titanium

- Labor costs: Steel replacement requires 300% more labor hours than titanium

Petrochemical facilities' industry case studies show that converting to titanium fasteners cuts maintenance expenses by 60% to 75% over 15 years. Operational efficiency is greatly affected by getting rid of regular replacement intervals and emergency maintenance.

Calculations for risk assessment demonstrate that titanium fasteners fail less than 0.1% of the time, whereas steel fasteners fail 3-8% of the time in corrosive conditions. This dependability advantage means lower insurance rates and less liability risk for important uses.

If you require fasteners for jobs where failure would have serious effects or where maintenance is hard to get to, titanium solutions are better since they are very reliable and last a long time.

Industry Applications Where Longevity Matters Most

Most specific industries benefit greatly from titanium fasteners that last a long time since they have strict operating needs and significant costs of failure. In aerospace, titanium micro screws are used for engine parts, structural assemblies, and avionics mounting systems. The cost of replacing them may be more than $10,000 each time they need to be serviced.

Titanium fasteners are very important for making medical devices since they are used for:

- Orthopedic implants that need to last for more than 20 years

- Surgical tools that need to be biocompatible and resistant to sterilizing

- Dental uses where the safety and health of the patient are the most important things

Marine engineering uses titanium in offshore platforms, undersea parts, and desalination equipment, all of which are exposed to seawater and are quite corrosive. Because of safety rules and problems getting to the areas, replacement costs in these situations are sometimes more than $50,000 each maintenance intervention.

Chemical processing plants use titanium fasteners for pipe systems, heat exchangers, and reactor vessels that deal with corrosive materials. Because it can handle strong acids, bases, and organic solvents, titanium is essential for these uses.

If you need fasteners for subsea applications or chemical processing equipment, then titanium micro screws are more suitable due to their proven performance in the harshest corrosive environments known to industry.

Quality Standards and Certifications for Titanium Fasteners

To guarantee continuous performance and dependability, titanium fasteners must meet strict international requirements for quality assurance. ASTM B348 sets standards for the mechanical qualities, chemical composition, and testing of titanium and titanium alloy bars. ISO 5832 sets standards for biomedical uses.

Manufacturing standards encompass these critical areas:

- Tracking materials from raw titanium ingot to the end product

- Using coordinate measuring equipment to check dimensional tolerances

- Analysis of surface finish to make sure it is as corrosion-resistant as possible

For aerospace applications, AS9100 certification requires full quality management systems that include things like configuration management, supplier qualification, and statistical process control. Implantable devices need to be FDA-compliant and have ISO 13485 certification for medical use.

According to ASTM E8 standards, testing techniques check for tensile strength, yield strength, elongation, and impact resistance. For pitting resistance, we use the ASTM G48 technique, and for cyclic polarization analysis, we use the ASTM G61 method.

If you need certified titanium fasteners for sectors that are regulated, like aerospace or medical devices, you should work with suppliers that have complete quality systems and full traceability paperwork. This will help you make sure that the fasteners meet all the rules and work as they should.

Conclusion

Titanium fasteners last longer than regular fasteners because they are very resistant to corrosion and may cure themselves by forming an oxide layer. The initial cost of titanium micro screws pays off in the long run since they need less maintenance, last longer, and are more reliable. Titanium's unique mix of strength, corrosion resistance, and biocompatibility makes it a great choice for industries that need high-performance fastening solutions. The scientific proof that titanium doesn't rust, together with performance data from important uses in the real world, shows that titanium fasteners are the best option for tough situations where failure has serious repercussions and durability is most important.

Chuanglian's Advanced Titanium Micro Screws Solutions

Chuanglian makes titanium micro screws with very precise engineering that are better than the industry norms for corrosion resistance and mechanical performance. Our factory in Baoji, which is renowned as China's "City of Titanium," has been working with titanium for more than 10 years. This knowledge allows us to make fasteners that satisfy the highest standards.

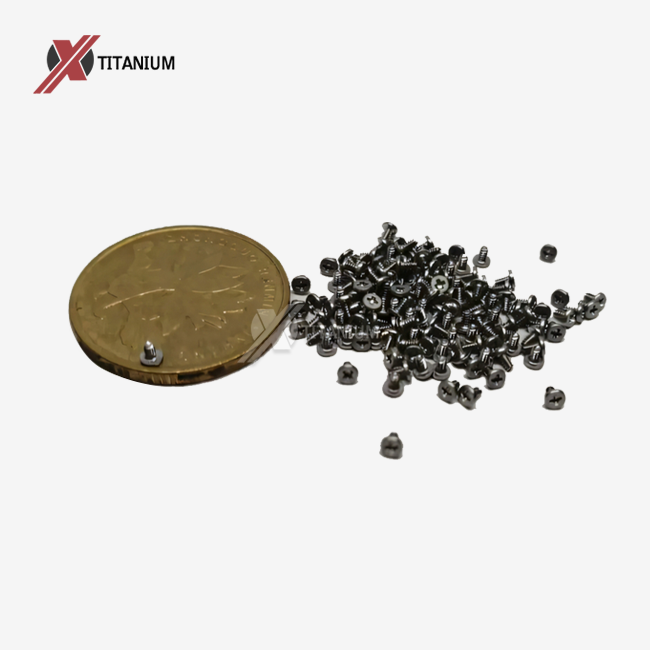

We have a wide range of products, including titanium micro screws in sizes M1 to M3. These screws are made from Grade 5 (Ti-6Al-4V) titanium alloy utilizing cutting-edge CNC machining methods. To make sure that the dimensions are accurate within ±0.02mm tolerances and the surface finishes match Ra 0.8μm standards, each fastener goes through strict quality control testing. Our crew can help you with whatever kind of finish you need, whether it's natural titanium, anodized hues like gold, blue, green, purple, black, or rainbow coatings. We are a reputable provider of titanium micro screws with AS9100 and ISO9001 certifications. We promise that the quality will always be the same and that the delivery times will always be accurate. Contact us at info@cltifastener.com or djy6580@aliyun.com for technical consultation and quotations.

References

1. Boyer, R.R. "An Overview on the Use of Titanium in the Aerospace Industry." Materials Science and Engineering: A, vol. 213, 1996, pp. 103-114.

2. Schutz, R.W. "Environmental Behavior of Beta Titanium Alloys." JOM Journal of the Minerals, Metals and Materials Society, vol. 46, no. 7, 1994, pp. 24-29.

3. Donachie, M.J. "Titanium: A Technical Guide, Second Edition." ASM International, Materials Park, OH, 2000.

4 .Rack, H.J. and Qazi, J.I. "Titanium Alloys for Biomedical Applications." Materials Science and Engineering: C, vol. 26, 2006, pp. 1269-1277.

5. Peters, M. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, vol. 5, no. 6, 2003, pp. 419-427.

6. Craig, B.D. "Handbook of Corrosion Data for Titanium." ASM International, Materials Park, OH, 1995.