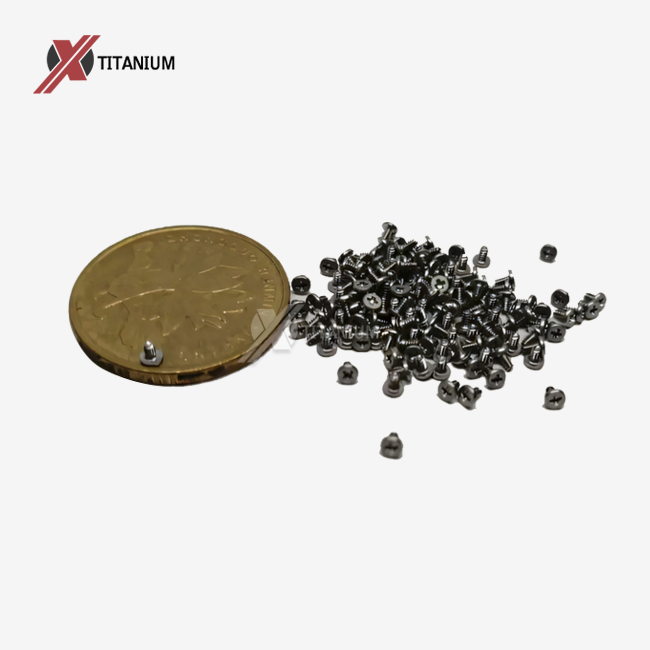

One of the best CNC titanium components manufacturers in China is Baiji Chuanglian New Metal Material Co., Ltd. They make precision-engineered goods like high-quality titanium micro screws for use in aerospace, medical, and industrial settings. Chuanglian is located in Baoji City, which is known as the "City of Titanium." The company has been processing titanium for more than ten years and has advanced CNC machining capabilities that allow it to make parts that meet the highest industry standards for biocompatible, corrosion-resistant, and high-strength applications.

Understanding China's Titanium Micro Screw Manufacturing Excellence

Strategic Geographic Advantages

China's titanium manufacturing sector has grown to be a major player on the international stage, especially in places like Baoji, which is home to the world's biggest titanium production base. The concentration of raw material suppliers, processing plants, and research organizations produces an environment that makes it easier to make specialist parts like titanium micro screws for medical and dental use. This regional clustering lowers supply chain costs and makes it possible to quickly make prototypes for bespoke orthopedic and surgical uses.

Advanced Manufacturing Capabilities

Chinese companies have spent a lot of money on CNC machining tools that are made specifically for working with titanium alloys. Modern facilities use multi-axis CNC machines that can make titanium micro screws with tolerances of ±0.01mm for precise applications. Using modern tools, controlled environments, and specific cutting settings, we can consistently make biocompatible implant parts and small implant fixtures that exceed international medical device requirements.

Cost-Effectiveness Without Compromise

The benefits of manufacturing go beyond decreased labor costs to include better use of materials, faster processes, and economies of scale. Chinese titanium processors have come up with new ways to recycle titanium shavings and better cutting techniques that cut down on waste while keeping the strength of high-strength titanium alloy parts. This efficiency means that bone fixation hardware and surgical tools may be sold at reasonable prices without losing quality.

Essential Criteria for Selecting Reliable Titanium Micro Screw Manufacturers

Technical Capabilities Assessment

Check out manufacturers based on how precise their CNC machining is, how well they handle materials, and how clean their clean rooms are for sterile uses. Find businesses that are skilled in working with different types of titanium, such as Grade 2 pure titanium and Grade 5 Ti-6Al-4V alloy. The maker should know a lot about threaded micro components and be aware of the problems that come with machining lightweight materials at tiny sizes.

Quality Management Systems

Reliable manufacturers have thorough quality control procedures that include checking incoming materials, keeping an eye on the process, and checking the finished product. Coordinate measuring machines (CMMs) and surface roughness testers are examples of advanced metrology equipment that make sure that each titanium micro screw satisfies the required dimensions and surface smoothness. Statistical process control strategies help keep manufacturing batches consistent.

Supply Chain Stability

Look into the manufacturer's ties with suppliers of titanium raw materials, especially their capacity to get certified medical-grade materials with the right paperwork. Stable suppliers have extra stock on hand for important grades and have built partnerships with many smelters to avoid problems with supply. This reliability is highly important for keeping delivery schedules for medical device manufacture that has to be done quickly.

Technical Support and Engineering Collaboration

The leading manufacturers provide full technical help at every stage of the product development process. This includes advice on how to choose materials, optimize designs, and test particular applications. Engineering teams need to know what biointegration requirements are for implant applications and be able to change thread profiles, head configurations, and surface treatments to meet the demands of each patient.

Traceability and Documentation

For medical and aeronautical uses, it's important to be able to track materials all the way from the raw material heat lot to the final inspection. Manufacturers must keep complete records, such as chemical composition certifications, mechanical property test results, and reports of dimensional inspections. This paperwork helps with regulatory filings and makes it easy to respond quickly to any quality investigations.

Critical Certification Requirements for Titanium Components

ISO 13485 Medical Device Standards

Manufacturers of titanium micro screws for medical use must have their ISO 13485 accreditation, which shows that they follow medical device quality management systems. This certification includes standards for medical devices' design controls, risk management, and post-market monitoring. Regular audits make sure that companies keep up with changing rules and regulations.

Material Grade Certifications

Different uses need different grades of titanium with verified chemical and mechanical characteristics. ASTM F136 certification is for surgical implants, while ASTM F67 certification is for dental implants made of commercially pure titanium. For all biocompatible goods, manufacturers must provide mill test certifications and keep track of where the original material came from.

Aviation Industry Standards

AS9100 certification is needed for aerospace applications. It improves on ISO 9001 by adding standards for managing configurations, validating designs, and managing suppliers. Titanium parts used in airplanes must also meet certain material standards, such AMS 4928 for Ti-6Al-4V bar stock and AMS 4911 for sheet materials.

Environmental and Safety Certifications

RoHS compliance means that titanium parts don't have any banned compounds in them. REACH certification, on the other hand, makes sure that chemicals are safe for the European market. ISO 14001 accreditation for an environmental management system shows a commitment to environmentally friendly production, which is becoming more important in the medical device and aerospace sectors when making purchasing choices.

Effective Sourcing Channels and Professional Platforms

Industry Trade Shows and Exhibitions

You can see how well manufacturers can accomplish their jobs at medical device shows like Medica Düsseldorf and AAMI. Aerospace trade exhibitions like the Farnborough International Airshow show off the newest titanium processing technology and let you talk directly with technical teams. These events let you see how advanced a company's production and technical skills are by looking at their booths and seeing product demos.

Professional Association Networks

The International Titanium Association (ITA) and the Medical Device Manufacturers Association (MDMA) are two groups that keep lists of authorized suppliers and provide advice on how to qualify suppliers in their fields. These organizations frequently help OEMs find certified titanium processors by setting up technical committees and working groups that concentrate on certain applications.

Digital Procurement Platforms

Specialized B2B platforms that deal with medical device parts and aerospace materials include advanced search features and services to verify suppliers. Capability matrices, certification status, and peer assessments from other procurement experts are common features of these platforms. Advanced filtering options make it possible to find suppliers who are experts in micro orthopedic screws and surgical hardware.

Technical Publication and Research Networks

Industry magazines and research organizations often showcase pioneering firms and groundbreaking innovations. Technical papers given at conferences often talk about collaborations with suppliers and might give you an idea of a company's production capabilities and quality performance. Collaborations with academics also show that a manufacturer is dedicated to improving and coming up with new ideas all the time.

Strategic Approaches to OEM/ODM Partnership Development

Design Collaboration Frameworks

Early engagement of suppliers in product development is necessary for OEM collaborations to work. Manufacturers with good technical skills may help with choosing the right titanium alloy, optimizing thread design, and figuring out how to make things. Collaborative design reviews can find problems before you spend money on equipment and speed up the time it takes to get new goods to market.

Intellectual Property Protection

Make sure everyone knows who owns the design, who may make it, and what the rules are for keeping things private. ODM agreements sometimes require sharing proprietary designs and manufacturing methods, therefore strong IP protection is quite important. Think about enforcement methods that are particular to each jurisdiction, and be sure to include rules for technology transfer and limits on where production may take place.

Quality Agreement Development

Comprehensive quality agreements provide requirements for inspections, acceptance, and taking remedial action. These agreements should include strategies for statistical sampling, standards for dimensional inspection, and paperwork for certifying materials. Clear steps for escalation and supplier audits make sure that quality stays high throughout the collaboration.

Technology Transfer and Scaling

Plan for production to go from a prototype to a lot of units. Protocols for transferring technology should include standards for validating processes, qualifying equipment, and training operators. Think about the rules that come with moving your production site and keep your options open for future growth in capacity or geographic diversity.

Effective MOQ Negotiation and Pricing Strategy Development

Understanding Manufacturer Cost Structures

Setting up CNC programming, tooling, and quality systems for titanium micro screw manufacturing costs a lot of money. Manufacturers usually set minimum order quantities (MOQs) based on these fixed costs and the minimum amounts of materials they need to buy. When you know what these cost drivers are, you can negotiate better order quantities and price structures that work for both sides.

Volume Commitment Strategies

Annual volume commitments can lead to better prices than negotiating prices for each purchase. Scheduled releases on blanket purchase orders provide producers a clear view of their production plans and purchasers get good prices. Think of using volume tier pricing that promotes growth and gives people reasons to buy from one place.

Material Cost Management

The pricing of titanium raw materials might change a lot depending on how much is available and how the market is doing. Talk about pricing methods that keep prices competitive while also giving you some protection against changes in material costs. For long-term contracts, think about including terms that allow for changes in the cost of materials. When it's suitable, look into using materials that customers provide.

Payment Terms and Risk Sharing

Payment conditions frequently affect the final price. For example, manufacturers might lower their working capital expenses by offering rebates for early payment. Think about risk-sharing agreements for developing new products. These might include splitting the price of tools and development. Pricing based on performance that is linked to quality measurements and delivery performance helps make sure that suppliers' goals are in line with customers.

Comprehensive Factory Audit and Quality Assurance Protocols

Manufacturing Environment Assessment

Check the cleanliness, environmental controls, and equipment maintenance requirements of the production facilities. Medical device applications need regulated conditions that keep things clean and make sure that processing can be done in a sterile way. Check the methods for handling titanium, the storage conditions, and the steps taken to keep it from being contaminated throughout the whole manufacturing process.

Process Capability Studies

Look at the process capability data for the most important features and dimensions of titanium micro screws. Statistical process control charts should show that processes are stable and have capability indices (Cpk) higher than 1.33 for important characteristics. Machine capability studies check how well equipment works and give you faith that the maker can always reach tight tolerances.

Quality System Effectiveness

Check the quality management systems of audits to make sure they are thorough, work well, and promote a culture of continuous improvement. Look at the procedures for corrective and preventive action (CAPA), managing suppliers, and dealing with customer complaints. Good quality systems show that you are managing risks ahead of time and have a planned way to increase quality.

Personnel Qualifications and Training

Check the credentials of the workers, the training programs, and the ways to check their skills. CNC operators who deal with titanium need to know a lot about cutting settings, how to choose the right tools, and how to handle materials. Quality inspectors should know how to use precise measuring tools and comprehend the concepts of GD&T.

Identifying Leading Supplier Characteristics in 2026

Advanced Manufacturing Technology Integration

Industry 4.0 technology including IoT sensors, real-time process monitoring, and predictive maintenance systems have been used by top manufacturers. These technologies make it possible to make unique titanium parts with uniform quality, shorter lead times, and better traceability. Advanced data analytics tools help with ongoing process improvement and predicting quality.

Sustainability and Environmental Responsibility

Leading suppliers show their commitment to sustainable production by using energy-efficient equipment, cutting down on waste, and recycling titanium in a responsible way. More and more, companies are choosing suppliers based on their efforts to reduce their carbon footprint and use renewable energy. Top performers stand out because they are open about their environmental reporting and have third-party sustainability certifications.

Global Supply Chain Resilience

The top firms have made their supply chains strong by getting materials from many different places, being able to change their production capacity, and managing their inventories strategically. Having raw material sources and processing capabilities in several parts of the world protects against problems in one area. Putting money into systems that make the supply chain more visible lets you control risks and talk to customers before they happen.

Innovation and R&D Capabilities

To improve titanium processing processes and find new uses for titanium, top suppliers put money into research and development. Working with universities and research institutes shows that you are committed to new ideas. Technical publications, patent portfolios, and involvement in the creation of industry standards show that someone is a thought leader and has technical knowledge.

Conclusion

When choosing the best titanium micro screws manufacturer in China, you need to carefully look at their technical skills, quality systems, and how well they fit with the needs of your unique application. China is a great place to get high-quality titanium parts since it has a lot of benefits when it comes to production, modern processing methods, and low prices. Success relies on carefully evaluating suppliers, making explicit quality agreements, and managing relationships on a continuing basis. Companies like Baoji Chuanglian New Metal Material Co., Ltd show how advanced China's titanium sector is when it comes to production. They have the skills and quality systems needed for tough aerospace, medicinal, and industrial uses. Companies may get world-class titanium micro screw production while still meeting the quality and reliability criteria they need for their most important uses by following systematic supplier assessment procedures and building solid relationships.

FAQ

Q1: What are the minimum order quantities typically required for custom titanium micro screws?

A: The minimum order quantity for bespoke titanium micro screws depends on how complicated they are and what they need to do. Usually, it is between 100 and 1,000 pieces. Manufacturers like Chuanglian regularly collaborate with clients to discover viable MOQ solutions that meet both their needs for cost-effectiveness and their needs for inventory, especially in the medical device and aerospace industries where lower volumes are prevalent.

Q2: How long does it take to receive samples and production orders for biocompatible titanium micro screws?

A: Making a sample usually takes 7 to 14 days, depending on how complicated it is and how busy the company is right now. Standard amounts of production orders usually take 2 to 4 weeks, however this might take longer for big orders or orders with special requirements. Medical-grade parts may need more time for paperwork and packing that is free of germs.

Q3: What surface treatments are available for titanium micro screws used in medical applications?

A: Common surface treatments include natural titanium finish, anodizing in different hues, and specialty coatings for better biointegration. Surface texturing or coating methods that help osseointegration are commonly used in medical settings. Manufacturers may provide technical advice on how to choose the right surface treatments for certain therapeutic uses.

Partner with Chuanglian for Premium Titanium Micro Screw Solutions

Chuanglian makes the best titanium micro screws for the most demanding uses in the aerospace, medical device, and precision manufacturing sectors. We can do a lot of things, including work together on bespoke designs, use sophisticated CNC machining, and have strict quality control systems that make sure everything works the same way every time and meets all rules. Are you ready to talk to our expert technical team about your needs for titanium micro screws? Contact us at info@cltifastener.com and djy6580@aliyun.com to discover how our titanium micro screws manufacturer expertise can support your next project.

References

1. International Titanium Association. (2024). Global Titanium Industry Review: Manufacturing Capabilities and Quality Standards.

2. Medical Device Quality Assurance Council. (2023). Best Practices for Titanium Medical Component Procurement and Supplier Qualification.

3. Aerospace Materials Specifications Committee. (2024). Titanium Fastener Standards and Certification Requirements for Aircraft Applications.

4. Chinese Titanium Industry Association. (2023). Annual Report on Titanium Processing Capabilities and Export Quality Performance.

5. Journal of Biomedical Materials Research. (2024). Advances in Titanium Micro Screw Design for Orthopedic and Dental Applications.

6. Industrial Supply Chain Management Review. (2023). Strategic Sourcing of Precision Titanium Components: Asia-Pacific Market Analysis.