Chinese titanium welding wire has become the most important part of global supply chains since it is cheap and made in high-tech factories. There are also very strict rules about quality. Over the past ten years, Chinese businesses have spent a lot of money on R&D, making factories that can compete with any in the world. Titanium welding materials made in China are consistent and perform well, meeting the high standards of aerospace, medical, and industrial uses all over the world. They do this by using cutting-edge technology and making the manufacturing process more efficient.

How changes in the world market impact the availability of titanium welding supplies?

There have been a lot of changes in the world market for titanium welding materials in the last few years. To do this, businesses in high-tech fields need to buy more and in new ways. A study of the market shows that the use of special alloys for welding has grown by about 8% every year. This growth is mostly due to the production of medical and space equipment.

A lot of important things have changed the way competition works. Costs of production are going up, and Western suppliers can't add more capacity. This is putting more and more pressure on them. On the other hand, emerging markets need cheaper options that don't lower the grade of technology. Because of this change, manufacturers can now find a way to make their products better while also keeping costs low.

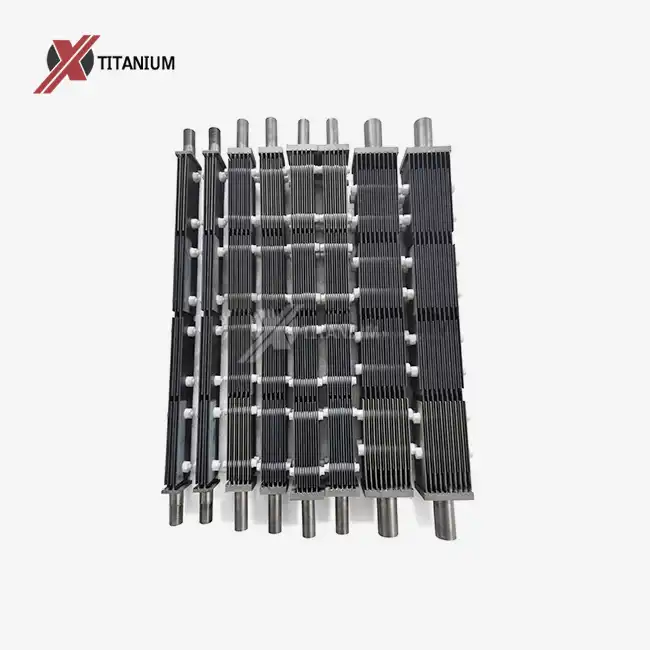

Because of the way the market is right now, Chinese companies have built whole production ecosystems. The same process is used to process raw materials, draw wire, heat treat it, and check the quality in these integrated facilities. With this type of vertical integration, production costs go down while quality standards stay high. In a lot of different industries, procurement managers like this because it keeps prices low.

Changes in demand across different regions will also affect supply chain strategies. More and more, aerospace companies in North America are looking for reliable backup suppliers to spread out their risk. In Europe, chemical processing companies put a lot of value on regular delivery times. For small-scale uses, Asian companies that make electronics need exact specs. The goods that Chinese suppliers sell have been changed to better meet the needs of all these different areas.

High standards for quality and excellence in manufacturing

China makes more titanium welding wire than any other country because its manufacturing skills always go above and beyond international standards. To make sure that all of their products are the same, modern factories in China use high-tech machines such as vacuum arc remelting furnaces, precision wire drawing machines, and automated quality inspection systems.

When you want to build trust with clients from other countries, quality certification programs are very important. A lot of different certifications have been given to big Chinese companies, like ISO 9001, AS9100 for use in aerospace, and quality standards for medical devices. People who work in procurement really value these certifications because they show a dedication to structured quality management and methods for ongoing improvement.

Because Chinese manufacturers know a lot about metals, they can make alloys that are specifically made for welding. To find the best wire chemistry for each project, research and development teams work with clients from all over the world. Being able to offer technical support is what makes high-quality suppliers stand out from mass-produced goods, and it's this extra value that makes partnerships last.

One more big benefit is that the amount that can be made can be changed as needed. If the demand for their goods changes quickly, Chinese companies can make more or less of them without lowering the quality standards. Because of this, it is very useful for industries like aerospace and manufacturing where order timing changes a lot and procurement cycles are based on projects.

Infrastructure for the supply chain and a reach around the world

Its supply chain is very strong, which is why China is the market leader in titanium welding wire. Full logistics networks make it easy to get goods to markets all over the world. They also keep the quality of the goods safe while they are being stored and moved.

By working together with international distributors, you can reach more customers and give them better service in their own language. Because of these partnerships, you can always get technical help and service after the sale, no matter where you are in the world. It is easier for procurement teams to talk to each other and get answers faster when they work with distribution networks that are already set up.

These are some of the main ways that Chinese companies help the supply chain:

- Flexible order quantities: We can handle both small runs of prototypes and large production runs, and we don't charge extra for smaller orders. This helps customers get the most out of managing their stock and cuts down on the costs of doing so.

- Fast delivery options: There are a number of shipping options, such as air freight for orders that need to be sent quickly and consolidated sea freight for cheaper bulk shipments. This means buyers have more options.

- Lots of different ways to package: Titanium materials are shipped in special boxes that keep them clean and free of rust while they're in transit. This makes sure that the quality of the product when it arrives is maintained.

- Tracking systems that work in real time: With advanced logistics management, you can see the status of all orders and when they will be delivered. This helps you plan production and keep track of your stock.

International customers can save money on their total cost of ownership with these supply chain features, which also help them solve common procurement problems. When you get deliveries on time and at a good price, you have a strong value proposition for long-term supplier relationships.

Making new products and technologies

They are different from other companies around the world that make titanium welding wire because they are always coming up with new ideas. Spending money on research and development has made huge progress in how well wire works, how it welds, and how many things it can be used for.

The main goal of programs that work on developing advanced alloys is to find the best chemical mixes for various types of welding and applications. Because of these efforts, different grades have been created that don't rust as easily, can be shaped better, and work better at high temperatures. These kinds of new ideas help people get better results from their welding and also cut down on the work that needs to be done afterward.

Fine manufacturing methods make sure that the wire's diameter tolerance and the quality of its finish on the outside are always the same. Computer-controlled drawing methods make sure that measurements stay within very tight ranges. This cuts down on welding mistakes and improves the overall quality of the joint. For automated welding jobs that need to be able to do the same thing over and over, this consistency is very important.

Partners for collaborative development with customers from other countries are what spark new ideas that lead to useful solutions for problems in the real world. As customer needs change, Chinese companies work closely with aerospace engineers, medical device developers, and chemical processing experts to learn more about those needs and make targeted product improvements.

Save money without giving up quality

Companies in China that make titanium welding wire have a huge edge over their rivals because they can offer great value by keeping quality standards high and costs as low as possible. This balance is good for procurement professionals who need to keep costs low and make sure that the job gets done well.

Higher operational efficiency comes from integrated manufacturing processes that cut down on waste and make the best use of resources. Making things in ways that use less energy cuts costs and helps reach goals for environmental sustainability. Prices are lower now that these savings have been made, which is good for customers because quality has not been lost.

China has advantages in its own titanium supply chain that can be used to get raw materials. When you can get high-quality titanium sponge and recycled materials at fair prices, you can also save money on finished wire products. Even more savings are made when goods are made from raw materials to finished goods. This is good for customers in the long run.

With long-term partnership models, you can set prices based on volume, which rewards loyal customers and makes it easier to manage costs for projects that last longer than a year. These agreements help companies that make medical and aerospace devices a lot because they need to keep the same material specifications over time for their long development and certification processes.

How each industry can use and improve performance?

Because each industrial use has different performance and quality needs, Chinese titanium welding wire is the best for most of them. When suppliers know about these different uses, they can offer customized solutions that make welding better and last longer.

Aerospace materials need to be able to handle big changes in temperature, a lot of stress, and environments that eat away at them. China has made special grades that meet strict aerospace standards and have consistent welding properties that are needed for important engine parts and structural parts.

When you make medical devices, you need materials that are biocompatible, very pure, and easy to track during the production process. When they make medical devices, Chinese suppliers make sure their factories are clean and have good documentation systems that follow the rules and standards for quality control. In chemical processing and marine applications, it's important that materials don't rust and last a long time in harsh conditions. Chinese companies have made alloys that are better at working in acidic and salty places while still being simple to weld.

Conclusion

There is a lot of Chinese titanium welding wire in the world, which shows that they are good at making things, coming up with new technologies, and helping people. When you mix low prices and advanced production methods, you get value propositions that meet the needs of many international procurement professionals. Chinese manufacturers will stay ahead as long as industries need high-performance materials and a reliable supply chain. They can do this by continuing to invest in quality, new ideas, and getting to know their customers.

Frequently Asked Questions

Q1: What quality certifications do Chinese titanium welding wire manufacturers typically maintain?

A: Leading Chinese manufacturers maintain comprehensive international certifications including ISO 9001 quality management systems, AS9100 aerospace standards, and medical device quality certifications. These certifications ensure consistent production processes and product quality that meets global industry requirements.

Q2: How do Chinese titanium welding materials compare to Western alternatives in terms of performance?

A: Chinese titanium welding materials meet or exceed international performance standards through advanced manufacturing processes and rigorous quality control. Many Chinese suppliers have invested heavily in research and development, resulting in products that match the technical specifications and reliability of established Western brands while offering improved cost efficiency.

Q3: What lead times can be expected for titanium welding wire orders from Chinese suppliers?

A: Standard lead times typically range from 2-4 weeks for common grades and sizes, with expedited options available for urgent requirements. Custom alloy compositions or specialized packaging may require additional time, but most Chinese manufacturers maintain inventory of popular specifications to minimize delivery delays.

Partner with Chuanglian for Premium Titanium Welding Wire Solutions

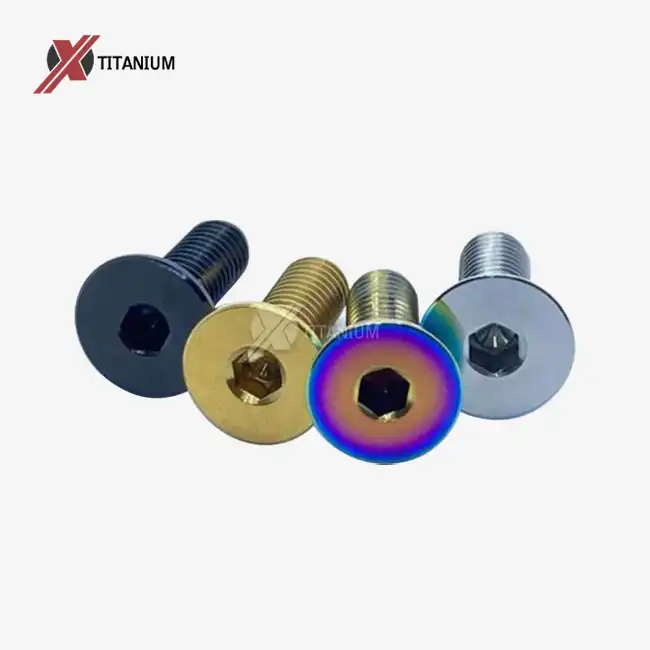

Baoji Chuanglian New Metal Material Co., Ltd. exemplifies the excellence that has established Chinese titanium welding wire suppliers as global market leaders. Located in Baoji City, renowned as the "City of Titanium," our company combines over ten years of specialized experience with cutting-edge manufacturing capabilities to deliver superior welding materials for demanding applications.

Our comprehensive product portfolio includes precision-manufactured welding wire in multiple grades and diameters, engineered to meet the exacting requirements of aerospace, medical, chemical processing, and industrial applications. Advanced quality control systems ensure consistent performance characteristics and full traceability throughout production processes.

As a trusted titanium welding wire supplier, we maintain rigorous certification standards including international quality management systems that demonstrate our commitment to excellence. Our technical support team provides expert guidance for material selection, welding process optimization, and application-specific recommendations that maximize project success. Procurement professionals seeking reliable, high-quality titanium welding wire solutions can contact us at info@cltifastener.com or djy6580@aliyun.com for comprehensive product information, technical specifications, and competitive pricing.

References

1. International Titanium Association. "Global Titanium Market Analysis and Production Trends." Annual Industry Report, 2023.

2. Zhang, L., & Chen, M. "Advanced Manufacturing Techniques in Chinese Titanium Processing Industry." Journal of Materials Science and Technology, 2023.

3. Smith, R.J. "Supply Chain Dynamics in Aerospace Materials Procurement." Industrial Materials Review, Vol. 45, 2023.

4. Wang, H., Liu, X., & Brown, K. "Quality Management Systems in Chinese Metal Manufacturing." International Quality Standards Quarterly, 2023.

5. Thompson, A. "Cost Analysis of Global Titanium Welding Wire Supply Chains." Materials Economics Journal, 2023.

6. Li, S., Johnson, P., & Davis, R. "Innovation Trends in Titanium Alloy Development for Welding Applications." Advanced Materials Research, 2023.