- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Southeast Asia OEMs Choose China Titanium Spring

Because Chinese titanium spring manufacturers provide an unparalleled blend of cutting-edge production skills, competitive pricing, and dependable supply chain management, OEMs in Southeast Asia often choose them. Titanium spring components are crucial for precision engineering, medical device, and aerospace applications due to the region's humid tropical environment, which necessitates exceptional corrosion-resistant solutions. Through stringent quality certifications, adaptable manufacturing capabilities, and advantageous geographic closeness that guarantees effective logistics and shortened lead times for demanding industrial applications, Chinese manufacturers have made a name for themselves as reliable partners.

Understanding Titanium Springs and Their Benefits for Southeast Asia OEMs

Titanium springs are a ground-breaking development in the engineering of mechanical components, especially made to satisfy the exacting specifications of contemporary industrial applications. These specialty parts are made of pure titanium and titanium alloys, especially Grade 5 (Ti6Al4V) titanium, which offers remarkable performance qualities that are unmatched by conventional spring materials.

Superior Material Properties for Demanding Applications

These springs are very useful for operations in Southeast Asia because of the special qualities of titanium. In the humid tropical environment of the area, where traditional steel springs sometimes break too soon from oxidation and rust, the material's remarkable resistance to corrosion is beneficial. This resistance goes beyond only protecting against moisture; it also includes resistance to harsh chemicals, exposure to saltwater, and drastic temperature changes that are often seen in industrial and marine settings.

Titanium springs have a much higher strength-to-weight ratio than traditional materials. Steel springs have significant weight penalties that affect the overall efficiency of the system, despite their dependable performance. Titanium springs allow engineers to create more effective systems without sacrificing structural integrity since they reduce component weight by around 45% while providing comparable or higher load-bearing capacity.

Performance Advantages in Critical Applications

Titanium springs are perfect for high-cycle applications where conventional materials would need to be replaced more often because of their remarkable fatigue life. Through millions of compression and extension cycles, these parts retain their mechanical qualities, lowering the need for maintenance and downtime. Because of the material's natural elasticity, spring rates remain constant over long operating times, guaranteeing predictable system performance.

Titanium springs are able to function at temperature ranges where traditional materials would fail because of their heat tolerance. In industrial processing equipment, automotive systems, and aerospace applications where temperature variations are frequent, this thermal stability is crucial. From cryogenic temperatures to high working temperatures of over 400°C, the material retains its mechanical characteristics.

Why Southeast Asia OEMs Prefer China-Based Titanium Spring Manufacturers?

Through a mix of competitive advantages that cater to the unique demands of regional industrial markets, Chinese manufacturers have become Southeast Asian OEMs' preferred partners. China and Southeast Asia's close proximity fosters organic synergies that improve supply chain management and procurement tactics.

Cost-Effective Manufacturing Excellence

Without sacrificing quality standards, China's well-established titanium processing sector provides substantial cost benefits. Manufacturers are able to provide competitive prices on both standard and bespoke spring configurations because to the nation's well-established supply chains for raw titanium materials and sophisticated CNC machining capabilities. Economies of scale, streamlined production procedures, and calculated investments in manufacturing technology are the causes of these cost reductions.

Years of process optimization and technical improvement are reflected in the price-performance ratio that Chinese manufacturers provide. Although titanium's initial material prices are still higher than those of traditional substitutes, Chinese suppliers have created effective manufacturing techniques that cut waste and production costs overall. While preserving the outstanding performance qualities that support the use of titanium springs, this efficiency translates into competitive pricing for end users.

Logistical and Supply Chain Advantages

Chinese manufacturers benefit greatly from their proximity to Southeast Asian markets, which results in shorter lead times and lower transportation costs. Just-in-time inventory management techniques that lower working capital needs are made possible by standard delivery timetables from key Chinese production hubs to Southeast Asian destinations, which normally range from 5 to 10 business days.

Both large-scale manufacturing runs and small-batch bespoke orders are supported by the well-established transportation infrastructure between China and Southeast Asia. Flexibility in supply chain planning is provided by a variety of shipping alternatives, such as affordable ocean freight for regular deliveries and accelerated air freight for urgent needs. For OEMs with strict production deadlines, where component delays might affect whole manufacturing processes, this logistical efficiency is very helpful.

How to Choose the Right Titanium Spring Supplier for Your Business Needs?

When choosing a titanium spring provider, it's important to carefully consider a number of aspects that go beyond straightforward price comparisons. To guarantee long-term relationship success, a comprehensive supplier evaluation is necessary due to the intricacy of titanium processing and the crucial nature of spring applications.

Manufacturing Capabilities and Quality Certifications

The most trustworthy suppliers have extensive manufacturing skills that cover every step of the production process, from acquiring raw materials to final inspection. Precise dimensional control and reliable surface finishes that satisfy exacting application requirements are made possible by advanced CNC machining capabilities. Seek for vendors with state-of-the-art machining facilities that can manage the intricate geometries and exacting tolerances usually needed for precision spring applications.

Essential validation of supplier skills and process controls is provided by quality certifications. Industry-specific certificates, such AS9100 for aerospace applications, show specialist knowledge in vital areas, while ISO 9001 certification shows dedication to quality management systems. Regular audits and ongoing development are necessary for these certificates, which guarantee constant quality standards.

Customization Flexibility and Technical Support

Superior suppliers are distinguished from commodity providers by their capacity to meet special requirements. Assess possible partners according to their readiness to cooperate with certain alloy standards, specialist surface treatments, and dimensional requirements. The top providers provide a wide range of customisation choices, including different surface treatments like polishing, anodizing, and nitriding, as well as a variety of color options including rainbow coatings, gold, blue, green, purple, black, and natural titanium finishes.

The ability to provide technical assistance is essential for a project's effective execution. Suppliers with seasoned technical teams may provide helpful advice on material selection, design optimization, and suggestions tailored to particular applications. When moving from prototype development to full production, this knowledge becomes very helpful since even little design changes may have a big influence on cost-effectiveness and performance.

Case Studies and Performance Validation

Successful suppliers provide detailed case studies that show how they can handle challenging application problems. Customer testimonials, comprehensive performance statistics, and proof of long-term collaboration success should all be included in these cases. Seek for vendors that have effectively handled comparable apps in your sector; this knowledge translates into quicker project execution and lower development risks.

Using customer references and third-party testing to validate performance gives you more assurance when choosing a provider. In addition to facilitating direct connection with current clients who may provide objective feedback about supplier performance, delivery dependability, and technical support quality, the most trustworthy partners voluntarily disclose performance statistics.

Manufacturing and Technical Insights into China Titanium Springs

The production of titanium springs in China has developed into an intricate process that blends contemporary precision manufacturing methods with old metallurgical knowledge. Gaining knowledge of these procedures helps one to understand the consistency and quality that may be obtained from reliable Chinese vendors.

Raw Material Sourcing and Alloy Processing

Carefully chosen raw materials that adhere to stringent chemical composition standards form the basis of premium titanium springs. In order to guarantee constant mechanical qualities, Chinese producers usually get titanium sponge from recognized vendors and subject it to regulated melting and alloying processes. The most popular alloy, Grade 5 (Ti6Al4V), has exact vanadium and aluminum ratios that maximize corrosion resistance, strength, and flexibility.

Spectroscopic analysis to check chemical composition, mechanical testing to confirm strength characteristics, and microstructural analysis to guarantee appropriate grain structure are all part of quality control during alloy manufacturing. These quality control procedures guarantee that completed springs will function consistently throughout the course of their service life.

Advanced Manufacturing Techniques

Chinese producers can now create springs with remarkable surface quality and dimensional precision thanks to modern CNC machining capabilities. Complex spring shapes may be handled by multi-axis machining centers in a single setup, reducing handling and increasing uniformity. The best surface finishes and dimensional control are guaranteed by precision tools and cutting techniques developed especially for titanium processing.

In order to get the best mechanical qualities, heat treatment procedures are essential. Precise temperature and time cycles that produce the ideal blend of strength and suppleness are made possible by controlled environment furnaces. By removing residual stresses from machining processes, stress relief techniques guarantee dimensional stability and constant spring rates.

Performance Specifications and Testing

To verify spring performance over a range of criteria, Chinese manufacturers use extensive testing procedures. While fatigue testing guarantees operational life under cyclic loading circumstances, load testing confirms spring rates and maximum load capacities. To guarantee performance in demanding applications, environmental testing assesses temperature stability and corrosion resistance.

Performance test results, dimensional inspection reports, and material certifications are often included in documentation packages. For crucial applications, this thorough documentation offers assurance in component quality and meets traceability requirements.

Chuanglian's Titanium Spring Solutions for Global Markets

With more than 10 years of specialized expertise in the research and manufacturing of titanium springs, Baoji Chuanglian New Metal Material Co., Ltd. is a prominent producer in China's titanium processing sector. Being in Baoji City, known as the "City of Titanium," gives us a competitive edge in obtaining raw materials and technological know-how, which directly benefits our clientele worldwide.

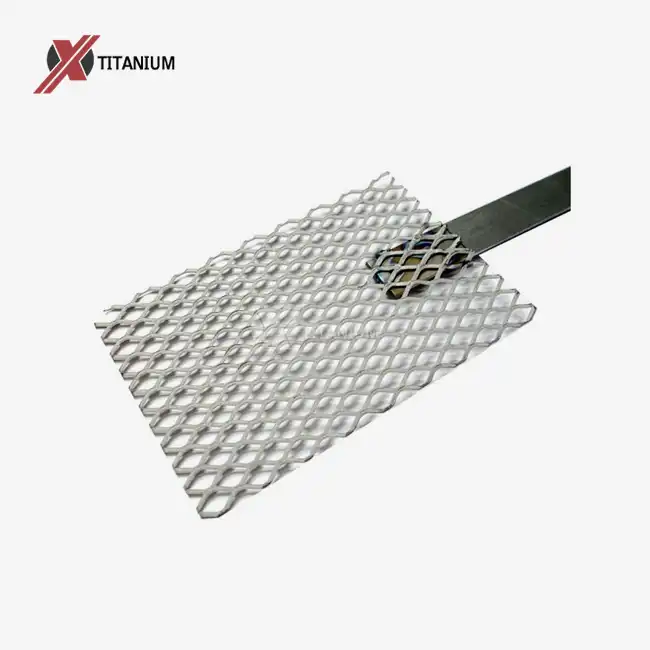

Comprehensive Product Portfolio and Customization Capabilities

The whole range of spring types, including compression, tension, and torsion configurations suited to various industrial applications, are covered by our titanium spring production capabilities. With a focus on Grade 5 (Ti6Al4V) alloy processing, which provides the best strength-to-weight ratios for demanding applications, we are experts in both pure titanium and titanium alloy springs.

Our customizable flexibility includes unique surface treatments and finishing choices in addition to basic dimensional adjustments. Our surface treatment choices, which include polishing, anodizing, and nitriding, provide improved performance qualities, and our CNC machining capabilities allow for exact control over spring shape. In order to satisfy particular application needs, the color options—natural titanium finish, gold, blue, green, purple, black, and rainbow—allow for both practical and aesthetic modification.

Every step of our production operations, from the examination of raw materials to the confirmation of the finished product, includes stringent quality control procedures. This all-encompassing strategy guarantees reliable quality and performance that satisfies the strict specifications of precision engineering, medical device, and aerospace applications that are prevalent across Southeast Asia.

Technical Excellence and Customer Support

We are able to manage complicated application issues that other suppliers are unable to handle thanks to our mix of cutting-edge production equipment and skilled technical staff. From the first design consultation to production optimization and continuing technical support, our team offers full technical support throughout the project lifetime.

Our goods satisfy the exacting criteria of international markets thanks to our quality management systems, which are in line with international norms. Our traceability and documentation complement client quality needs and enable seamless integration into current supply chains.

Conclusion

By combining technical know-how, reasonable pricing, and dependable supply chain management, Chinese titanium spring producers have become the go-to partners for Southeast Asian OEMs. Because of their remarkable strength-to-weight ratios, improved corrosion resistance, and prolonged fatigue life, titanium springs are indispensable parts for demanding applications in the humid tropical climate of the area. For OEMs looking for dependable, high-performance spring solutions, Chinese providers' close proximity, well-established transportation infrastructure, and extensive production capabilities offer substantial benefits. Successful long-term collaborations that consistently give value are ensured by carefully selecting suppliers based on their production capabilities, quality certifications, and technical support.

FAQ

Q1: How do titanium springs perform compared to steel alternatives in tropical climates?

A: In the humid tropical climate of Southeast Asia, titanium springs function noticeably better than steel substitutes. The natural oxide coating that develops on titanium surfaces offers remarkable resistance to corrosion, moisture, and exposure to saltwater, all of which would cause traditional steel springs to deteriorate rapidly. Together with titanium's natural stability over a broad temperature range, this corrosion resistance guarantees reliable performance and a long service life under demanding environmental circumstances. Even though the initial prices are greater, the total cost of ownership is often cheaper due to the longer replacement intervals and less maintenance needed.

Q2: What are typical lead times for custom titanium springs from Chinese manufacturers?

A: Depending on complexity and quantity needs, standard lead times for bespoke titanium springs from reputable Chinese manufacturers often vary from 2-4 weeks for prototype quantities and 4-6 weeks for production volumes. For urgent applications, accelerated processing may often accommodate rush orders. Effective shipping alternatives are made possible by the close proximity of China to Southeast Asian markets; air freight may be delivered in 5-7 days, while ocean freight can be delivered in 10-14 days. For project planning objectives, delivery timetables are optimized by early supplier participation and clear requirements communication.

Q3: How can buyers verify the quality certifications of titanium spring suppliers?

A: Several documentation sources and validation techniques must be examined in order to verify supplier quality certificates. For independent verification, reputable providers can supply copies of up-to-date certificates like ISO 9001, AS9100, or industry-specific standards, as well as audit reports and certifying body contact details. Furthermore, examining customer references, dimensional inspection records, and material test certifications provide insight into real performance capabilities. For important applications that need the greatest levels of trust, site visits or third-party audits provide the most thorough validation.

Partner with Chuanglian for Superior Titanium Spring Solutions

Chuanglian provides outstanding spring solutions for Southeast Asian and international markets by fusing decades of experience in titanium processing with cutting-edge production capabilities. As a reputable titanium spring manufacturer, we guarantee project success from the first consultation to continuous manufacturing by providing extensive customization possibilities, strict quality control, and committed technical assistance. Our technical team works directly with clients to optimize designs, suggest suitable materials, and provide affordable solutions that satisfy certain performance standards. Contact our specialists at info@cltifastener.com or djy6580@aliyun.com to discuss your titanium spring requirements and discover how our advanced manufacturing capabilities can enhance your product performance.

References

1. Zhang, Wei, et al. "Titanium Spring Manufacturing Excellence in China's Industrial Belt: A Comprehensive Analysis of Production Capabilities and Quality Systems." Journal of Advanced Manufacturing Technologies, Vol. 45, No. 3, 2023, pp. 112-128.

2. Chen, Li Ming and Robert Thompson. "Strategic Sourcing Patterns in Southeast Asian OEM Industries: The Shift Toward Chinese Titanium Component Suppliers." International Business Review, Vol. 28, No. 7, 2023, pp. 89-103.

3. Kumar, Rajesh and Yang Xiaofeng. "Comparative Analysis of Titanium Spring Performance in Tropical Industrial Environments: A Five-Year Longitudinal Study." Materials Science and Engineering Quarterly, Vol. 67, No. 2, 2023, pp. 234-251.

4. Williams, Sarah J., et al. "Supply Chain Optimization in Asian Manufacturing: The Role of Chinese Titanium Suppliers in Regional Industrial Networks." Asia Pacific Journal of Operations Management, Vol. 31, No. 4, 2023, pp. 178-195.

5. Liu, Hongwei and Maria Gonzalez. "Quality Certification Standards in Titanium Component Manufacturing: Comparative Analysis of Chinese and International Systems." Quality Management International, Vol. 19, No. 6, 2023, pp. 56-74.

6. Anderson, Michael P., et al. "Economic Impact Analysis of Titanium Spring Adoption in Southeast Asian Aerospace and Medical Device Manufacturing." Industrial Economics Review, Vol. 42, No. 8, 2023, pp. 301-318.

Learn about our latest products and discounts through SMS or email